The advent of Computer Numerical Control (CNC) devices has brought about a significant transformation in contemporary production methods. Given their remarkable adaptability, precision, and efficiency, they have emerged as a crucial component within numerous global industries. The utilization of three- and four-axis CNC machines is prevalent across a diverse array of applications. This comprehensive investigation will analyze the various characteristics, advantages, disadvantages, applications, and difficulties associated with these devices.

Unraveling the 3-Axis CNC Machine

CNC (Computer Numerical Control) machines have become essential in numerous industries, serving as a crucial component in the transformative advancements occurring across a diverse array of economic sectors. The 3-axis computer numerical control (CNC) machine is particularly notable among the range of versatile tools available. The simultaneous execution of tasks along the X, Y, and Z axes has significantly enhanced its appeal, rendering it the preferred choice for a wide range of projects.

Key Characteristics of a 3-Axis CNC Machine

The exceptional functionality of the 3-axis CNC machine is a result of its remarkable capacity to move in three dimensions (X-axis, Y-axis, and Z-axis). The machine’s ability to switch between vertical and horizontal cutting allows for unprecedented accuracy. Let’s have a look at a table that summarizes the most important features of this remarkable equipment.

Key Characteristics of a 3-Axis CNC Machine

| Characteristics | Description |

|---|---|

| Axes of Motion | Works on X, Y, and Z axes |

| Complexity | Medium |

| Machining Strategy | Primarily suited for vertical and horizontal machining |

| Cost | Generally less expensive |

| Operator Skill Level | Lower level of skill needed |

Intriguing Possibilities of a 3-Axis CNC Machine

In comparison to its multi-axis cousins, the 3-axis CNC machine operates on a more straightforward foundation. Despite its apparent lack of complexity, it provides numerous interesting opportunities that make it a viable choice for many enterprises. Let’s investigate what makes this machine so interesting now.

- Affordability: The low price tag of the 3-axis CNC machine is one of its main selling points. Three-axis CNC machines are typically less expensive than their more complex, multi-axis counterparts. Because of this, they’re great for companies on a tight budget or trying out CNC for the first time;

- Ease of Use: The 3-axis CNC machine’s user-friendliness stems from its inherent simplicity. Fewer axes to manipulate mean less complicated controls and less time spent learning how to use the equipment. Because of how simple it is to operate, organizations may quickly implement it into their production procedures;

- Efficiency with 2D Cuts: When it comes to making flat or block-like components, the 3-axis CNC machine really shines. Its strength in 2D cuts makes it ideal for work that doesn’t call for precise 3D machining.

Pros and Cons of a 3-Axis CNC Machine

The 3-axis CNC machine, like any other technological equipment, has both advantages and disadvantages. Let’s weigh the benefits and drawbacks more closely:

| Benefit | Description |

|---|---|

| Affordability | Since 3-axis CNC machines are typically less expensive than their 5- and 6-axis counterparts, they are a popular option for enterprises on a tighter budget. |

| Ease of Use | Three-axis CNC machines are often less complicated to use and require less training due to having fewer axes to manage. |

| Efficiency with 2D Cuts | Since these machines are so good at making precise 2D cuts, they are best suited for making items that are flat or block-like. |

| Limitation | Description |

|---|---|

| Restricted Flexibility | Due to their inability to function along more than three axes, 3-axis machines are not as versatile as their higher-axis counterparts. Complex machining, such as undercuts, may be beyond their capabilities. |

| Manual Repositioning | Manual repositioning of the workpiece is necessary if machining from many angles is required. Particularly when dealing with complex or massive projects, this might lead to the possibility of errors and increased labour expenses. |

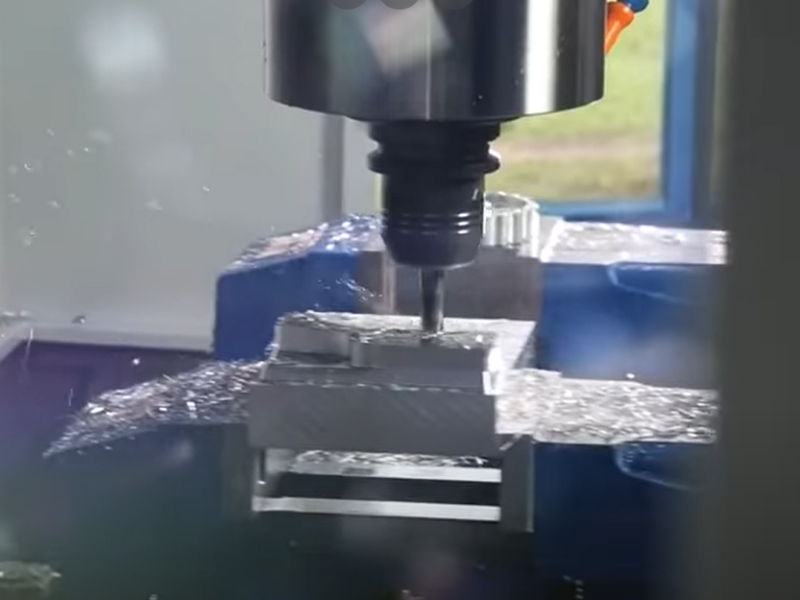

Viewing this video will help you understand the workings of a 3-axis CNC machine.

Decoding the 4-Axis CNC Machine

Computer numerical control (CNC) devices have completely changed the manufacturing business by allowing for the manufacture of extremely precise and complicated items. A major game-changer among these cutting-edge devices is the 4-axis CNC machine. This innovative tool expands upon the possibilities of a 3-axis machine by adding an X-axis (also called an A-axis) rotating turntable. Let’s dive into the details of the 4-axis CNC machine, examining its unique features, benefits, and drawbacks.

Key Characteristics of a 4-Axis CNC Machine

The 4-axis CNC machine has a lot of cutting and moving options, so it can make complex pieces with lots of different features. In the table below, we highlight the most salient features of this extraordinary device:

Key Characteristics of a 4-Axis CNC Machine

| Characteristics | Description |

|---|---|

| Axes of Motion | Works on X, Y, Z, and A (rotary around X-axis) axes |

| Complexity | High |

| Machining Strategy | Allows for multi-axis machining, including undercuts and side cuts |

| Cost | Generally more expensive |

| Operator Skill Level | Higher level of skill and training required |

Intriguing Possibilities of a 4-Axis CNC Machine

The additional A-axis of the 4-axis CNC machine opens up a wealth of opportunities that were previously unavailable with 3-axis machines. Let’s take a closer look at what makes this device so interesting:

- Increased Flexibility: The increased mobility and adaptability of a 4-axis machine is one of its primary benefits. With the addition of the rotating axis, it is now possible to move the machine in all directions around the workpiece, opening up a world of possibilities for the construction of intricately curved and contoured designs;

- Automated Rotation: The workpiece can be rotated automatically during milling thanks to the rotary axis that is incorporated right into the machine. Because of this, precision and efficiency are both increased while the requirement for manual repositioning is greatly reduced;

- Faster Production: In the manufacturing industry, time is money, and the 4-axis CNC machine is unrivalled in its ability to speed up the manufacturing process. It simplifies production by allowing for multiple complex cuts to be made in a single setup, increasing output without sacrificing quality.

Pros and Cons of a 4-Axis CNC Machine

The 4-axis CNC machine, like any other technical development, has both advantages and disadvantages. Let’s weigh the benefits and drawbacks more closely:

| Benefit | Description |

|---|---|

| Increased Flexibility | The greater range of motion and enhanced flexibility of the 4-axis machine makes it well suited for the creation of intricate shapes. |

| Automated Rotation | Automatic workpiece rotation via the integrated rotating axis eliminates the need for human repositioning and associated mistakes. |

| Faster Production | The machine’s capacity to execute complex cuts with just one setup bodes well for increased throughput. |

| Limitation | Description |

|---|---|

| Higher Costs | In general, 4-axis machines cost more than their 3-axis counterparts because they require more complex motion control systems. However, for companies working with complex designs, the benefits of these upgrades are typically worth the additional expense. |

| Increased Complexity | A 4-axis machine’s increased capability makes it more difficult to use, necessitating the expertise of a trained professional. To fully utilize its potential, in-depth knowledge and experience are required. |

This movie provides a comprehensive look at the inner workings of a 4-axis CNC machine.

Making the Decision: 3-Axis or 4-Axis?

Factors such as product complexity, production volume, budget, and operator skill level all play a role in deciding whether a 3-axis or 4-axis machine is more appropriate.

Decision Factors for Choosing Between 3-Axis and 4-Axis CNC Machine

| Factors | 3-Axis Machine | 4-Axis Machine |

|---|---|---|

| Product Type | Best for flat or block-like products | Ideal for intricate, complex designs |

| Volume of Production | Suited for both low and high-volume production | Excellent for high-volume production |

| Budget | More cost-effective | Higher initial investment |

| Operator Skill Level | Requires less training | Requires extensive training |

Conclusion

The selection of an appropriate CNC milling machine for a particular task is contingent upon various factors, including the specific requirements of the job, the volume of production, and the availability of suitable tools. Productivity and quality can be optimized through the acquisition of knowledge regarding the diverse range of options available, as well as a comprehensive understanding of their respective advantages and disadvantages.

FAQ

In both vertical and horizontal milling machines, the spindle always stays in the same position. Spindles that can tilt to different degrees are found on turret mills and some sophisticated CNC machines.

Because of its sturdy construction and capacity to handle heavy-duty jobs, horizontal and bed CNC milling machines are typically preferred for high-volume production.

The answer is yes. Vertical and horizontal milling are both possible on universal milling machines because of the turret that rotates around the machine’s column.