The evolution of industrial robots has revolutionized the manufacturing landscape, making them an integral part of modern industries. These versatile machines, capable of automating complex tasks, have significantly increased productivity and efficiency in various sectors. But, when did the idea of industrial robots first come to life? In this article, we’ll explore the fascinating history of industrial robot invention, tracing its inception, and understanding the significant milestones that paved the way for the transformative role of automation.

History of Industrial Robots

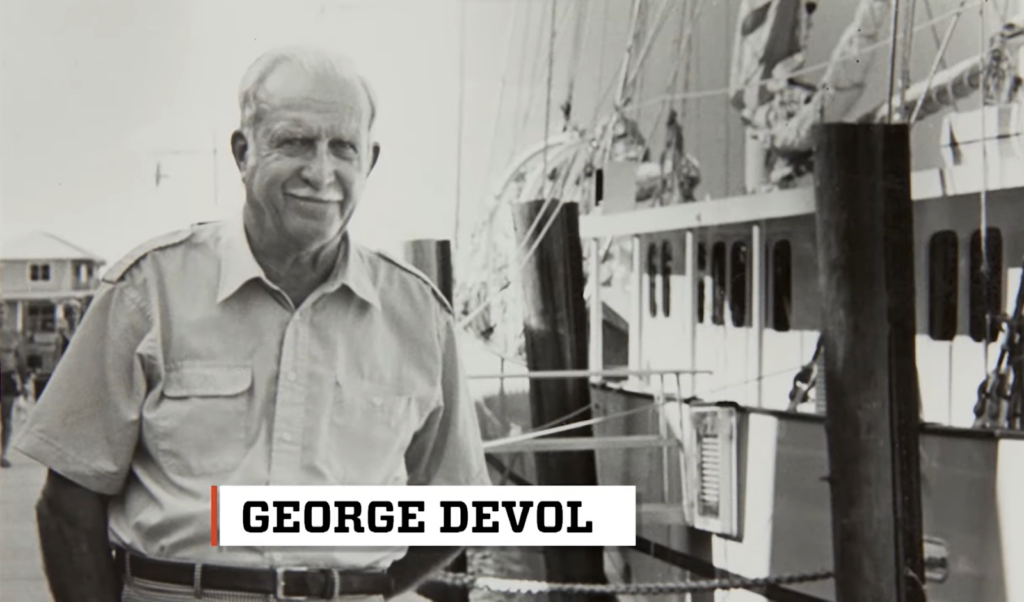

The history of industrial robots is more extensive than many might realize, stretching back to the 1950s. It was during this era that George Devol’s groundbreaking invention marked the birth of the first industrial robot, setting the stage for automation in manufacturing. These early machines were robust, weighing around two tons and equipped with hydraulic actuators, autonomously transferring objects from one point to another.

Over the decades, technology has driven significant evolution in automation systems. The integration of sensors, electronics, and computer software has propelled these machines to new heights, allowing them to tackle a diverse range of complex tasks with remarkable efficiency and precision. Today, industrial robots are versatile tools capable of welding, painting, assembly, packaging, palletizing, inspection, testing, and much more, all accomplished effortlessly.

The commercial adoption of automation systems began in the early 1960s, primarily focused on heavy lifting tasks. While the initial versions had limited programmability and were relatively rudimentary, they already showed great potential in boosting manufacturing productivity. As time went on, these early successes paved the way for continuous advancements in automation, leading to the impressive capabilities of modern industrial robots.

As industries sought to automate labor-intensive tasks, automation systems evolved to prioritize materials handling and precision work in the late 1960s and early 1970s. This period saw the introduction of smaller electric systems with advanced controls, microprocessors, and compact motors, making them well-suited for lighter assembly tasks, such as bolt and nut tightening.

By the late 1970s, automation systems had expanded their repertoire even further, taking on material transfer, painting, and arc welding, effectively assuming hazardous tasks in manufacturing facilities. Of particular note was their invaluable contribution to steel mills, operating in high-temperature environments and enhancing facility safety while allowing skilled laborers to focus on more critical manufacturing operations.

The journey of automation systems, from their early days as heavy hydraulic machines to their present form as agile, precise, and multifunctional tools, is a testament to the remarkable progress in automation technology. The future holds even more promise as continuous advancements pave the way for these machines to become indispensable partners in shaping the future of manufacturing and beyond. From automotive production lines to electronics manufacturing and beyond, industrial robots are poised to play an increasingly vital role in revolutionizing industries and improving efficiency on a global scale.

Types and features

There are six types of industrial robots, each designed for specific tasks and applications in manufacturing and automation. These versatile machines play a crucial role in streamlining production processes and increasing efficiency. The six types of industrial robots are:

| Robot Type | Description | Typical Applications |

|---|---|---|

| Articulated | Featuring rotary joints, these robots have a flexible structure that mimics the movement of a human arm. | Welding, painting, assembly lines |

| SCARA | Selective Compliance Assembly Robot Arm (SCARA) robots are known for their horizontal reach and vertical lift. | Pick-and-place operations in electronics assembly |

| Cartesian | Also known as Gantry or Cartesian Coordinate robots, they operate on three linear axes (X, Y, Z). | Packaging, material handling |

| Delta | Comprising three parallel arms connected to a central platform, Delta robots excel in high-speed, light-duty tasks. | Pick-and-place operations in food and pharmaceuticals |

| Polar | These robots have a rotating arm with a fixed base and are well-suited for tasks requiring extensive reach. | Material removal, inspection |

| Cylindrical | Characterized by a single rotary joint for rotation, cylindrical robots are mainly used for simple tasks. | Handling, machine loading, unloading |

First Industrial Robot

- The first industrial robot, known as Unimate, marked a groundbreaking milestone in the realm of automation;

- It was developed by George Devol and Joseph Engelberger in the 1950s, Unimate was a two-ton device equipped with hydraulic actuators, capable of autonomously transferring objects from one place to another.

Although a far cry from the agile and sophisticated robots of today, Unimate laid the foundation for the transformative role of industrial robots in manufacturing. Its introduction revolutionized production processes, leading to increased efficiency and productivity. From this humble beginning, the capabilities of industrial robots have vastly expanded, encompassing a wide array of complex tasks such as welding, painting, assembly, packaging, and more, driving innovation across industries and shaping the future of automation.

The Beginnings of Industrial Robots in Japan

In 1966, a momentous event marked the introduction of industrial robots in Japan, when Joseph Engelberger visited Tokyo. The renowned engineer and robotics pioneer delivered a lecture on the potential applications and benefits of industrial robots to an audience of around 700 executives. The enthusiastic question-and-answer session that followed lasted over two hours, solidifying Japan’s appeal as a promising market for Unimation, a company seeking business expansion in Asia.

Unimation’s goal was to enter the Japanese market and sought a technical partner capable of manufacturing its industrial robots precisely. Initially considering seven electrical manufacturers for this collaboration, Kawasaki Aircraft, the predecessor of Kawasaki Heavy Industries, was not on the initial list.

However, in 1967, Kawasaki Aircraft’s management learned of Unimation’s search for a technical partner in Japan. Seizing the opportunity, they promptly visited Unimation in the United States and initiated vigorous negotiations. Recognizing the growing demand for robotics in Japan’s rapidly expanding economy, Kawasaki Aircraft viewed venturing into the robotics field as a strategic move to address productivity challenges and labor shortages.

Although electrical manufacturers held an advantage in terms of machine control expertise, Kawasaki Aircraft’s accumulated technical capabilities, combined with the passion demonstrated by their management team, swayed Engelberger’s decision. Consequently, Unimation chose Kawasaki Aircraft as their technical partner in Japan.

In June 1968, Kawasaki Aircraft established the “Office for Promoting Domestic Production of Industrial Robot (IR)” in its Mechanical Division. By October of the same year, the formal technical license agreement with Unimation was inked, marking the beginning of the history of Kawasaki Robotics and the dawn of industrial robots in Japan. This crucial partnership laid the foundation for the widespread adoption of industrial robots in Japan and contributed significantly to the country’s remarkable advancements in automation technology.

The Evolution of Robotics in the 1980s

The 1980s were a pivotal decade in the evolution of robotic technology, laying the essential groundwork for the future of automation. During this period, significant advancements in various aspects of robotics transformed the capabilities and applications of robotic systems. Technological breakthroughs in microprocessors, sensors, and computer software led to more intelligent and versatile robots, capable of performing complex tasks with greater precision and efficiency.

In the manufacturing industry, robots became increasingly prevalent on assembly lines, handling tasks such as welding, painting, and material handling with remarkable speed and repeatability. The introduction of computer numerical control (CNC) further revolutionized industrial processes, enabling robots to carry out intricate machining operations with unmatched accuracy.

The 1980s also witnessed the emergence of mobile robots and robotic arms that could navigate and manipulate objects in unstructured environments. These developments opened up new possibilities for robotics applications beyond the factory floor, such as in space exploration, medical surgeries, and hazardous material handling.

Moreover, the concept of collaborative robotics began to take shape during this decade, where robots could safely work alongside humans, enhancing productivity and safety in various industries. The focus on human-robot interaction laid the foundation for today’s collaborative robots, or cobots, which play a crucial role in human-centric workspaces.

The 1980s marked a transformative period for robotic technology, setting the stage for the rapid advancements and widespread integration of robots in various sectors in the years to come. The innovations of this decade not only paved the way for increased automation but also inspired further research and development, leading us to the sophisticated and cutting-edge robotics we witness in the present day.

The Future of Industrial Robotics

Industrial robots of today have evolved into highly sophisticated and versatile machines, revolutionizing manufacturing processes across industries. Equipped with advanced sensors, artificial intelligence, and collaborative capabilities, modern industrial robots can handle complex tasks with precision and efficiency. From assembly and welding to material handling and quality inspection, they play a vital role in streamlining production, improving product quality, and ensuring workplace safety.

Looking towards the future, the trajectory of industrial robots holds even greater promise. Tomorrow’s robots are expected to be even more adaptive and agile, capable of seamlessly collaborating with human workers to optimize productivity. The integration of machine learning and data analytics will enable them to continuously learn and improve their performance, leading to enhanced automation and faster decision-making.

Furthermore, with advancements in soft robotics and biomimicry, industrial robots of the future may mimic the dexterity and flexibility of human hands, opening up new frontiers in delicate and intricate tasks. This human-like touch will pave the way for robots to excel in fields such as healthcare, where they can assist in surgeries and patient care.

Moreover, the increasing emphasis on sustainability and eco-friendly practices will drive the development of eco-conscious robots, ensuring resource-efficient and environmentally responsible manufacturing processes.

As artificial intelligence and robotics continue to converge, industrial robots will play a central role in the Fourth Industrial Revolution, also known as Industry 4.0. Through seamless connectivity and data exchange in smart factories, tomorrow’s robots will be part of a sophisticated network of machines, enabling real-time monitoring and optimization of production lines.

Conclusion

The invention of industrial robots marked a transformative moment in the history of manufacturing and automation. The birth of the first industrial robot, Unimate, in the 1950s laid the foundation for a new era of technological advancements that continue to shape industries to this day. From their humble beginnings as heavy hydraulic machines, industrial robots have evolved into sophisticated and versatile tools capable of handling complex tasks with precision and efficiency. As we move forward, the trajectory of industrial robots promises even greater possibilities, as they embrace advancements in AI, collaboration, and eco-consciousness. Today’s robots stand as a testament to human ingenuity and the relentless pursuit of innovation, driving us toward a future where automation and technology redefine the boundaries of what is possible in the manufacturing world.