In the world of design, engineering, and manufacturing, the terms “bevel” and “chamfer” refer to specific types of edge treatments. Both techniques serve a similar purpose of removing sharp edges, but they achieve this outcome in different ways. Understanding the distinctions between bevels and chamfers is crucial for selecting the right approach for various applications. In this article, we will explore the differences between bevels and chamfers, their applications, and the advantages they offer. So, let’s delve into the fascinating world of edge treatments.

Bevel

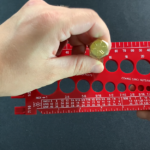

A bevel is an angled cut or sloping surface formed along the edge of a workpiece. Typically, the bevel angle is specified as the angle between the original surface and the cut surface. Bevels are usually created by cutting the material at an angle other than 90 degrees. This results in a sloping edge that can vary in width, depending on the specific requirements of the design.

Chamfer

On the other hand, a chamfer is a straight, flat cut made along the edge of a workpiece. Unlike a bevel, a chamfer does not introduce an angle between the original surface and the cut surface. Instead, it creates a symmetrical flat area by removing material from the edge at a 45-degree angle. Chamfers can also be customized with different angles, but the 45-degree chamfer is the most common and widely used.

Differences between Bevel and Chamfer

To better understand the dissimilarities between bevels and chamfers, let’s compare them side by side:

| Aspect | Bevel | Chamfer |

|---|---|---|

| Type of Cut | Angled cut | Straight cut along the edge |

| Angle | Not limited to 45 degrees | Typically 45 degrees |

| Edge Width | Can vary depending on design | Uniform width |

| Visual Impact | Less pronounced and gradual | Clearly defined flat edge |

| Sharpness | Retains some sharpness | Removes sharp edges completely |

| Machining | Requires more complex setup | Easier to machine |

| Applications | Weld preparation, aesthetics | Deburring, visual enhancement |

Applications of Bevels and Chamfers

Bevels and chamfers are versatile edge treatments that find numerous applications across various industries. Both these edge treatments serve specific purposes and contribute to the functionality, safety, and aesthetics of different products and materials. Let’s explore the unique and engaging applications of bevels and chamfers:

Applications of Bevels

| Industry | Application |

|---|---|

| Welding | Weld Preparation: Bevels are commonly used in welding applications, especially for thick metal plates. The sloping edges create a larger surface area for the weld, enhancing weld penetration and resulting in a stronger bond between the materials. |

| Woodworking | Aesthetics: Bevels add a touch of elegance and visual appeal to woodworking projects. When applied to edges of furniture, doors, and frames, they create a stylish and sophisticated look, enhancing the overall design. |

| Edge Softening: Bevels are employed to soften sharp edges on materials like glass or metal. This edge treatment makes handling safer and reduces the risk of injury from accidental contact. |

In welding, bevels play a crucial role in ensuring high-quality joints, especially when dealing with thick metal plates. The beveled edges create a V-shaped groove that provides ample space for the welding material to fill in, resulting in a strong and durable bond between the materials. This is particularly important in industries such as shipbuilding, construction, and heavy machinery manufacturing.

In woodworking and interior design, bevels are not only functional but also add an artistic dimension to the finished products. By adding bevels to the edges of furniture, doors, and frames, craftsmen can create a visually appealing and elegant look that sets their work apart.

Additionally, bevels are used to soften sharp edges, which is essential when dealing with materials like glass or metal. In architectural applications, bevels can be found on glass windows, doors, and panels, providing a smooth and safe surface to handle without the risk of cuts or injuries.

Applications of Chamfers

| Industry | Application |

|---|---|

| Manufacturing | Deburring: Chamfers are highly effective in removing burrs and sharp edges left after machining processes. This edge treatment enhances the safety and usability of the workpiece, making it more comfortable to handle. |

| Electronics | Assembly Ease: In the manufacturing of electronic devices and machinery, chamfers are strategically added to screw holes and openings. This design feature facilitates smoother and more efficient assembly processes, reducing the chances of misalignment during assembly. |

| Product Design | Cosmetic Enhancement: Chamfers are widely used in product design to add a touch of refinement and a professional appearance to various items. They can elevate the aesthetics of products such as gadgets, appliances, and consumer electronics. |

In the manufacturing industry, chamfers play a critical role in improving the overall quality of machined parts. After machining operations, burrs and sharp edges can be left behind, posing a safety risk and potentially affecting the functionality of the component. Chamfers effectively eliminate these imperfections, making the workpiece safer and more reliable.

For the electronics industry, chamfers on screw holes and openings are strategically placed to simplify the assembly process. The beveled edges guide screws into their designated positions, making it easier for assembly line workers to align and secure components accurately.

Furthermore, chamfers are used in product design to enhance the appearance of various items. Whether it’s the sleek chamfered edges of a smartphone or the elegant bevels on a luxury watch, these design features contribute to the product’s overall aesthetic appeal and perceived quality.

Advantages of Bevels and Chamfers

Bevels and chamfers offer distinct advantages in various applications, making them invaluable edge treatments in several industries. Let’s delve into the unique and engaging advantages of both bevels and chamfers through tables, bullet lists, and paragraphs:

Advantages of Bevels

| Advantage | Description |

|---|---|

| Improved Weld Quality | Beveled edges in welding create a V-shaped groove that allows for deeper and more effective welds. This results in stronger connections between the materials being joined. |

| Elegant Design | Bevels add a touch of sophistication and style to a wide range of products. Whether it’s furniture, doors, or architectural elements, bevels enhance the aesthetics, making them visually appealing and elegant. |

| Safety Enhancement | Bevels are an excellent way to eliminate sharp corners and edges on materials. By providing a smooth, sloping surface, bevels reduce the risk of accidents and injuries during handling and use. |

In welding applications, bevels play a pivotal role in achieving high-quality welds. The V-shaped groove created by beveled edges allows welders to penetrate deeper into the joint, ensuring better fusion and a more robust connection. This advantage is especially crucial when dealing with thick metal plates or critical welding applications, such as in structural engineering and pipeline construction.

Beyond their functional benefits, bevels also offer an aesthetic advantage. In architecture and design, beveled edges can transform mundane structures into visually stunning pieces of art. Whether it’s the refined edges of furniture or the stylish contours of a decorative trim, bevels elevate the overall design, adding a sense of elegance and sophistication.

Moreover, safety is a significant concern in various industries. Bevels address this by eliminating sharp corners and edges that could pose risks to workers or users. By softening the edges, bevels make materials safer to handle, reducing the likelihood of cuts and injuries.

Advantages of Chamfers

| Advantage | Description |

|---|---|

| Easy Machining | Creating chamfers is relatively simple compared to bevels. It involves a straight cut, typically at a 45-degree angle, without the need for complex angle adjustments. |

| Cost-Effective Deburring | Chamfers are an efficient and cost-effective method for removing burrs and sharp edges left after machining processes. By chamfering edges, manufacturers can ensure the final product meets quality standards without investing in complex deburring equipment. |

| Precise Fit | Chamfered edges aid in achieving precise fits during assembly processes. The beveled edges guide components into position, reducing the chances of misalignment or incorrect positioning. |

Chamfers offer several advantages, especially in manufacturing and assembly processes. When compared to bevels, creating chamfers is a simpler task. Machinists can achieve chamfers by making a straight cut at a specific angle, typically 45 degrees, without the need for intricate calculations or setups. This ease of machining reduces production time and costs, making chamfers a preferred choice for certain applications.

In manufacturing, chamfers serve as an effective deburring method. After machining operations, burrs and sharp edges may remain on the workpiece, affecting the product’s quality and safety. Chamfering these edges eliminates the burrs, ensuring the final product meets rigorous quality standards while keeping production costs in check.

Furthermore, chamfered edges facilitate precise fits during assembly processes. In industries like electronics and machinery manufacturing, where intricate components need to come together seamlessly, chamfers guide components into their designated positions. This aids assembly line workers in achieving accurate alignments and reduces the chances of misalignment, contributing to improved product performance and reliability.

Conclusion

Bevels and chamfers are distinct edge treatments, each with its unique characteristics and applications. Bevels offer a gradual, angled cut that finds use in welding and aesthetics, while chamfers provide a flat, 45-degree cut primarily for deburring and assembly ease. Understanding the differences between these edge treatments enables designers, engineers, and manufacturers to make informed choices when incorporating them into their projects. For a better understanding of these concepts, check out this video:

So, whether you’re crafting furniture, designing machinery, or welding metal components, bevels and chamfers are essential tools in your arsenal to achieve both functionality and visual appeal.

FAQ

Absolutely! Many designs use a combination of bevels and chamfers to achieve specific outcomes. For instance, a product may feature a beveled edge for aesthetics while incorporating chamfers for ease of assembly.

Both bevels and chamfers can be utilized in woodworking, depending on the desired look and functionality. Bevels are ideal for decorative edges, while chamfers work well for softening sharp corners and easing assembly.

Yes, various machining tools, such as routers and milling machines, can be equipped with specific bits or cutters to create bevels and chamfers accurately and efficiently.