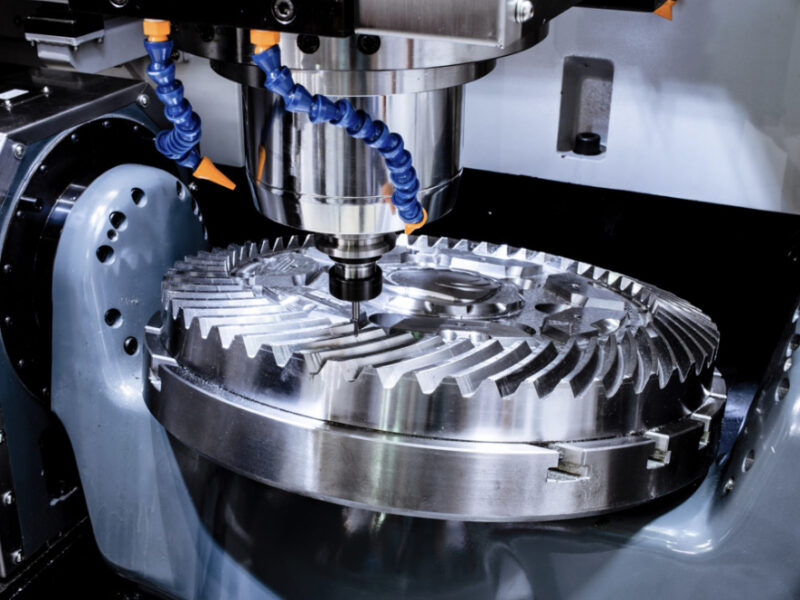

In the realm of modern manufacturing, CNC programming (Computer Numerical Control Programming) plays a pivotal role, enabling computer-controlled machines to execute intricate and accurate tasks. By creating a set of instructions, CNC programming guides the machine to transform raw materials into finished products with exceptional precision, speed, and consistency.

From Code to Craftsmanship

With CNC programming, the possibilities extend far beyond mere lines of code; it is an art that empowers machining tools to create extraordinary and intricate shapes from raw materials, resulting in remarkable and awe-inspiring creations. The ability to precisely control the movements and functions of the machine opens up a world of design potential, allowing manufacturers to craft products with unparalleled accuracy and finesse.

- However, mastering the art of CNC programming is no simple feat. The complexity of the tools and the machine’s responsiveness to the program’s instructions demand years of dedicated practice and hands-on experience. Novices entering this domain may initially find themselves overwhelmed by the intricacies involved. It requires a deep understanding of mathematics, geometry, and material properties, along with an intuitive grasp of how the machine will respond to various commands;

- Yet, the allure of CNC programming lies in its learnability. With determination and perseverance, even novices can gradually grasp the fundamentals and evolve into skilled CNC machine operators. Through continuous learning, trial, and error, they can unlock the true potential of these sophisticated machines, transforming their creative visions into tangible realities.

As CNC technology continues to advance, the barriers to entry may become more accessible, making it increasingly possible for aspiring programmers to embark on this exciting journey. Embracing CNC programming opens doors to innovation and revolutionizes the way we approach manufacturing, shaping a future where precision and efficiency go hand in hand, and where human ingenuity finds expression in the masterpieces crafted by these computer-controlled artisans.

More details

As CNC programming continues to evolve, the integration of artificial intelligence (AI) and machine learning (ML) technologies has emerged as a game-changer in the manufacturing industry. AI-driven CNC programming is revolutionizing the way machines interpret and execute instructions, leading to enhanced efficiency, reduced production time, and minimized errors. Through advanced algorithms, AI-powered CNC systems can analyze vast amounts of data, learn from past experiences, and optimize machining processes in real time. This technology empowers CNC machines to adapt and self-correct during operations, ensuring consistent and precise outcomes even in dynamic and unpredictable manufacturing environments.

With AI and ML at the helm of CNC programming, manufacturers can achieve new levels of automation and autonomy. Smart CNC machines can now anticipate and prevent potential errors, detect anomalies during the machining process, and make intelligent decisions on tool paths and cutting strategies. As a result, human intervention is minimized, and CNC operators can focus on higher-level tasks, such as design refinement and process optimization. Additionally, AI-driven CNC programming opens the door to predictive maintenance, where machines can predict when maintenance is required based on usage patterns, minimizing downtime and maximizing productivity.

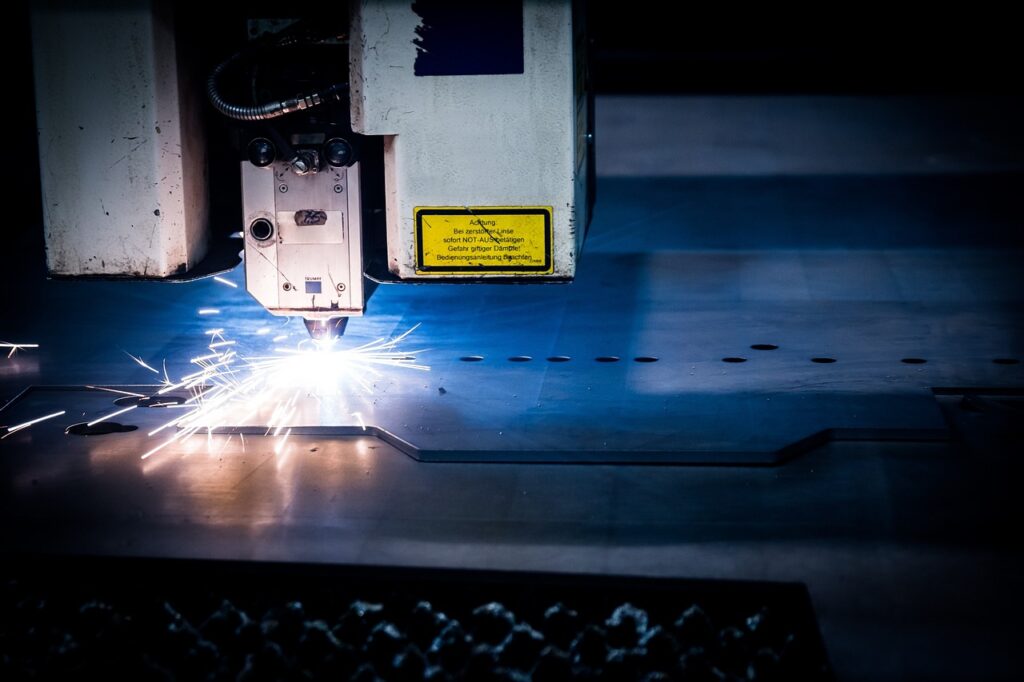

The increasing integration of additive manufacturing

It is also known as 3D printing, with CNC programming is another revolutionary development reshaping modern manufacturing. Combining the precision of CNC machining with the versatility and freedom of 3D printing brings forth a new era of hybrid manufacturing. In this paradigm, CNC machines are utilized to perform post-processing operations on 3D-printed components, allowing for the creation of intricate geometries that were previously unattainable using traditional subtractive manufacturing methods alone.

- Additive CNC manufacturing offers a myriad of advantages, including reduced material wastage, enhanced design flexibility, and faster prototyping cycles. By 3D printing the primary form of a complex component and then using CNC machining for fine-tuning and finishing touches, manufacturers can achieve exceptional levels of accuracy and intricacy;

- Furthermore, hybrid manufacturing enables the production of hybrid materials with a combination of dissimilar materials, expanding the possibilities for lightweight and high-performance components in industries like aerospace and automotive.

The marriage of CNC programming and additive manufacturing also paves the way for mass customization. Manufacturers can leverage the power of CNC to personalize and modify 3D-printed products according to individual customer requirements, delivering bespoke solutions without compromising on quality or efficiency. This fusion of technologies has unleashed a new wave of creativity, innovation, and cost-effectiveness in manufacturing, shaping a future where the boundaries of design and production are pushed further than ever before.

The Language of CNC: G-codes, M-codes, and Alphanumeric Codes

CNC machines primarily rely on G-codes and M-codes to control the machining process. G-codes dictate the positioning of the parts or tools, preparing them for cutting or milling. M-codes activate tool rotations and various functions. Additionally, for specific parameters like speed, tool number, cutter diameter offset, and feed, the system employs other alphanumeric codes starting with S, T, D, and F, respectively.

Exploring the Different Types of CNC Programming

- Manual CNC Programming: The Oldest and Most Challenging Variety

Manual CNC programming, the oldest form, requires programmers to anticipate the machine’s response and visualize the program’s outcome. It best suits straightforward tasks or situations demanding highly specific designs crafted by experts;

- CAM CNC Programming: Bridging the Gap with Software Aid

Ideal for those lacking advanced math skills, CAM CNC programming converts CAD designs into CNC programming language, simplifying the mathematical complexities of manual programming. It offers a middle ground between manual and conversational programming, providing more options and automation potential through CAD designs;

- Conversational or Instant CNC Programming: Beginner-Friendly Approach

Conversational programming is the easiest method for beginners, as it doesn’t require knowledge of G-code. Users can input essential details in simple language, allowing them to verify tool movements before execution. However, it has limitations when it comes to handling complex paths.

Finding the Right CNC Programming Type for Your Needs

Selecting the most suitable CNC programming type is a critical decision that hinges on one’s comfort level and experience with the system. For beginners, the intricacies of manual programming may appear overwhelming and could lead to potential errors. In such cases, CAM and conversational programming emerge as more accessible alternatives.

- CAM programming serves as an ideal choice for those aiming to machine complex and intricate designs. By leveraging software to convert CAD designs into CNC programming language, CAM simplifies the process and reduces the mathematical burden often associated with manual programming. This approach allows users to focus more on the creative aspects of their designs and less on the technical intricacies;

- On the other hand, starting with conversational programming provides an excellent entry point for novices. It allows users to interact with the machine using simple language, without the need for in-depth knowledge of G-codes. By gradually familiarizing themselves with the CNC machine’s functions and movements, beginners can build confidence and develop a solid foundation for their programming journey.

Ultimately, the best approach may vary depending on the complexity of the project, the user’s expertise, and their long-term goals in the world of CNC programming. Regardless of the chosen path, the journey promises to be rewarding, filled with creativity, and an ever-growing understanding of the intricate dance between human imagination and the limitless possibilities of computer-controlled precision.

The Essential CNC Programming Software

CNC programming relies on several software types, including:

- CAD (Computer-Aided Design): For modeling designs on the computer, eliminating the need for traditional paper-based methods;

- CAE (Computer-Aided Engineering): Used by engineers to fine-tune aspects like flow, heat dynamics, and optimization for specific functions;

- CAM (Computer-Aided Manufacturing): The most critical software, converting designs into CNC programming code to direct the machine.

Embarking on the Journey of CNC Programming for Beginners

Beginners should find user-friendly software that suits their needs, such as CAD and CAM integration. Strengthening math and computer programming skills will ease the learning process. Consistent practice and a structured learning schedule are vital to master CNC programming.

The Difficulty of CNC Programming: A Multi-Faceted Question

The complexity of CNC programming varies based on the programmer’s math and coordinate geometry understanding. The basics are relatively easy to grasp, but achieving mastery demands effort, practice, and skill. Seeking guidance from classes and continuous programming practice is essential for attaining expertise.

Tips for Beginner Success

Starting with small and simple projects allows beginners to gradually build skills and motivation for more challenging endeavors. Seeking help from instructors, forums, or online communities can also offer valuable assistance when facing obstacles.

Learning CNC Programming: Resources and Approaches

Numerous online and in-person resources are available for learning CNC programming. Formal classes provide a structured learning path, while self-guided learners can find books and courses designed for students or educators. For instance, the Primer for the SkillsUSA/VICA Championships from Industrial Press serves as an introductory course in CNC programming.

Conclusion

In conclusion, CNC programming is a crucial aspect of modern manufacturing, revolutionizing the industry by enabling computer-controlled machines to achieve remarkable precision and efficiency. The process involves creating instructions that guide the machines in transforming raw materials into intricate finished products. While mastering CNC programming may take time and practice, beginners can start with user-friendly software and gradually build their skills and expertise.

- The three main types of CNC programming – manual, CAM, and conversational – offer unique advantages and cater to different skill levels. Manual programming, although challenging, allows for highly specific designs and expert craftsmanship. CAM programming bridges the gap with software aid, simplifying mathematical complexities, while conversational programming serves as an accessible entry point for beginners;

- For success in CNC programming, consistent learning and practice are essential. Beginners should begin with small projects and seek guidance from instructors or online communities when facing difficulties. By continuously honing their skills, aspiring CNC programmers can unlock the potential to create intricate and innovative designs, contributing to the ever-evolving landscape of modern manufacturing.

Embracing CNC programming is not only about operating machines but also about unleashing creativity and transforming ideas into tangible reality. As technology advances and innovations emerge, the future of CNC programming holds endless possibilities, driving the manufacturing industry to even greater heights. Whether you are a novice or an experienced programmer, the journey of CNC programming promises a rewarding and fulfilling endeavor.