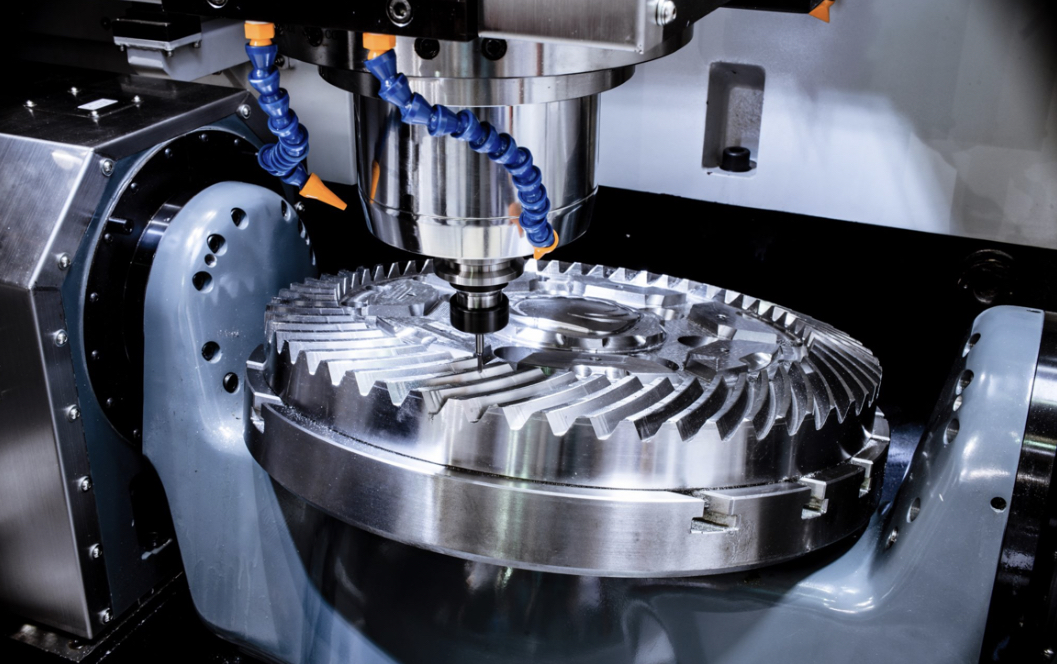

Moving industrial craft machines, particularly CNC machines, can be a complex and challenging task that requires careful planning and execution. These machines are not only expensive but also sensitive and essential for various manufacturing processes. To ensure a successful and stress-free relocation, this comprehensive guide provides expert tips and step-by-step instructions for moving industrial craft machines with ease.

Assessing the Machines and Surroundings

Before embarking on the relocation process, conducting a comprehensive assessment of the industrial craft machines and their surrounding environment becomes paramount. This critical step involves meticulous observation and documentation of various factors. Begin by meticulously noting down the dimensions, weight, and intricacies of the machines to ensure that the transportation arrangements can handle their specific requirements. Pay special attention to any delicate components that demand careful handling, ensuring they receive the appropriate protection throughout the move.

In addition to focusing on the machines themselves, it is equally essential to evaluate the accessibility of both the current and new locations. This evaluation entails scrutinizing factors such as door sizes, hallways, elevators, and any potential obstacles that may hinder the smooth movement of the machines during relocation. By identifying and addressing these challenges beforehand, you can strategize effectively to ensure a seamless and efficient move.

Furthermore, collaborating with experts in the field, including machinery movers and industrial relocation specialists, can prove instrumental in developing a comprehensive relocation plan. Their expertise can offer valuable insights and innovative solutions to streamline the entire process. This collaboration also ensures that necessary precautions are taken to prevent any damage to the machines or their surroundings.

Moreover, as part of the assessment, consider the infrastructure requirements at the new location to accommodate the craft machines. This includes assessing power supply, ventilation, and any other necessary utilities to guarantee a safe and optimal setup.

Finally, during the assessment, take note of any potential opportunities for optimization or improvement in the new location. This could include optimizing workflow, reorganizing the layout for better efficiency, or adopting new technologies that might enhance productivity and reduce downtime.

Creating a Detailed Moving Plan

A well-structured moving plan serves as the backbone of a successful relocation, leaving no room for oversight or uncertainty during the process. Its significance lies in its ability to provide a comprehensive roadmap, meticulously guiding every step of the way. The first step in crafting such a plan is to establish a detailed timeline, breaking down the entire relocation process into manageable phases and setting specific milestones for progress. This timeline allows for efficient coordination and ensures that each task is completed within the designated timeframe.

Moreover, a crucial aspect of the moving plan involves assigning clear responsibilities to individuals or teams involved in the relocation. By delineating roles and responsibilities, everyone knows their specific tasks and the level of accountability expected from them. This fosters a sense of ownership and teamwork, empowering each member to contribute their expertise and skills towards the collective success of the relocation.

To execute the moving plan seamlessly, it is imperative to assess the necessary equipment and resources. This includes everything from suitable packing materials to specialized machinery for lifting and transporting heavy or delicate items. By determining the required resources in advance, potential delays due to unavailability or last-minute arrangements are minimized, thus keeping the relocation on track.

Moreover, having a clear plan in place not only streamlines the logistics but also helps in anticipating and mitigating potential mishaps. With proper risk assessment, contingency plans can be formulated to address unexpected challenges that may arise during the relocation. This proactive approach equips the team with the tools and strategies needed to tackle unforeseen circumstances with confidence and efficiency.

Additionally, a well-structured moving plan serves as a communication tool, enabling effective coordination and collaboration among all stakeholders involved in the relocation. Regular progress updates and open channels of communication facilitate the smooth flow of information, ensuring that everyone is informed about the latest developments and any adjustments to the plan.

| Moving Steps | Short Description |

|---|---|

| Pre-Move Assessment | Assess machines, noting sizes, weights, and special handling requirements. Customize moving plan accordingly. |

| Assign Moving Team | Designate knowledgeable individuals to oversee the moving process, familiar with machine assembly and disassembly. |

| Establish Timeline | Set clear dates for disassembly, packing, transportation, and reassembly at the new location. |

| Hire Professional Movers | Seek experienced movers specialized in handling industrial craft machines for a secure and efficient move. |

| Obtain Permits and Clearances | Check and secure necessary permits and clearances for interstate or international transportation. |

| Create Detailed Packing Plan | Develop a comprehensive packing strategy, using padding and anti-static materials to protect delicate components. |

| Label and Document Components | Label and document components during disassembly for reference during reassembly. |

| Plan for Specialized Equipment | Arrange for specialized equipment like cranes or forklifts to handle heavy machinery during loading and unloading. |

| Consider Insurance Coverage | Verify sufficient insurance coverage from the moving company for protection during transit. |

| Coordinate with the New Location | Communicate essential details to the team at the new location, including expected arrival time and unloading requirements. |

| Test Run the Reassembly | Perform a trial reassembly to ensure smooth processes at the new site. |

| Plan for Unforeseen Delays | Prepare contingency plans to address unexpected delays or challenges during the move. |

| Communicate with Employees | Keep relevant personnel informed of the moving plan’s impact on production schedules to minimize disruptions. |

| Conduct Final Inspections | Perform a final inspection to secure machines adequately before transportation. |

| Post-Move Inspection and Testing | After the move, inspect and test all machines thoroughly to ensure proper functionality in the new location. |

Hiring Professional Movers or In-House Team

When contemplating the relocation of your CNC machines, it is essential to explore various options to guarantee a smooth and secure transition. One approach worth considering is enlisting the services of experienced industrial machinery movers. These professionals bring a wealth of expertise to the table, having dealt with numerous CNC machine relocations in the past. Their specialized knowledge ensures that every step of the moving process, from disassembly to packing, transportation, and reassembly at the new location, is executed with the utmost care and precision.

Industrial machinery movers are equipped with state-of-the-art tools and equipment, tailored to handle heavy and delicate machinery like CNC machines. Their proficiency in maneuvering such equipment ensures minimal risk of damage during the relocation process. With their guidance, you can rest assured that your CNC machines will be carefully disassembled, securely packed, and transported to their new destination in a timely and efficient manner.

Alternatively, if your company possesses an in-house team with significant expertise in handling CNC machines, it might be worth considering utilizing their skills for the relocation. However, it is crucial to assess their capabilities comprehensively, ensuring they have the necessary experience and training to carry out the move effectively. If your in-house team is well-versed in handling complex machinery relocations, this option could be cost-effective and suitable for the task.

Regardless of the approach you choose, prioritizing the safety and integrity of your CNC machines throughout the relocation process is paramount. Whether you opt for the expertise of professional movers or your in-house team, meticulous planning, attention to detail, and the use of appropriate equipment will play pivotal roles in ensuring a successful and stress-free transition for your valuable CNC machines.

Safely Disassembling the Machines

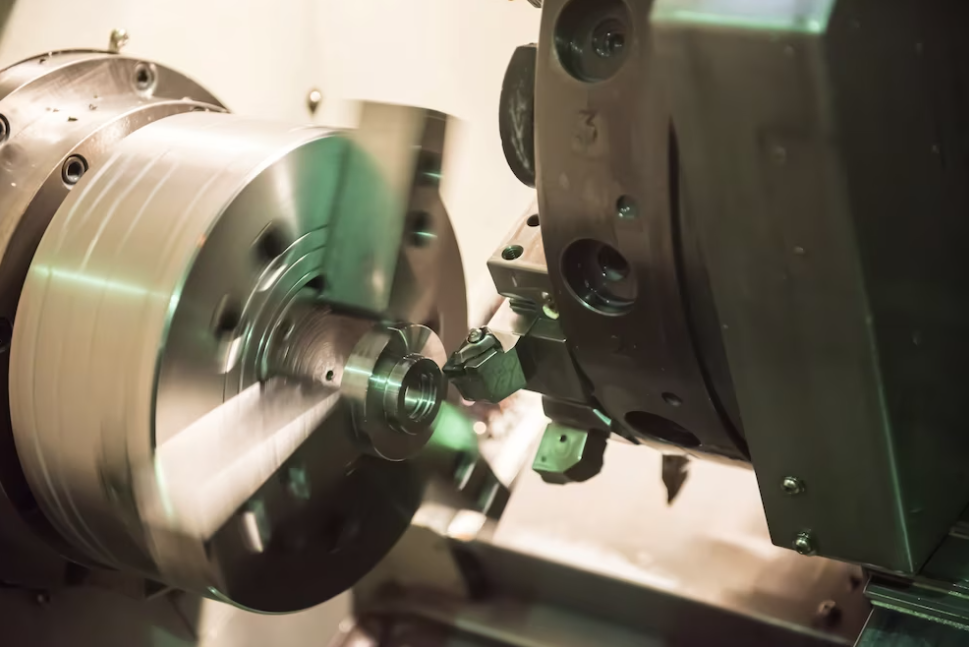

The process of relocating industrial craft machines necessitates a methodical approach to ensure their safe and successful transfer. The first step in this endeavor is the careful and precise disassembly of the machines, strictly adhering to the manufacturer’s guidelines and safety protocols. This meticulous process involves disengaging intricate components while paying close attention to the interconnections that make the machines function seamlessly.

To facilitate a seamless reassembly at the new location, it is imperative to label each component appropriately. By clearly marking and categorizing each part during disassembly, the reassembly process becomes more streamlined, minimizing the risk of confusion or errors. This labeling practice allows the reassembly team to swiftly identify and match the corresponding components, expediting the overall relocation process.

Additionally, a valuable technique to support the reassembly effort is to document the disassembly thoroughly. Capturing the process through photographs or videos serves as a valuable reference point during reassembly. These visual aids provide the reassembly team with a step-by-step guide, ensuring that every component finds its rightful place. They act as a safety net against potential uncertainties that may arise during the reassembly process, ultimately bolstering the efficiency and accuracy of the relocation.

Throughout the entire disassembly process, it is crucial to exercise caution and precision to safeguard the integrity of the industrial craft machines. Every step should be executed with a keen eye on preserving the condition and functionality of the components, as any damage during disassembly could lead to issues during reassembly or the future operation of the machines.

Securely Packing and Transporting

When preparing for the transportation of the machines, it is of utmost importance to give paramount attention to the packaging process.

- Each component must be meticulously packed to create a robust defense against any potential damage during transit;

- Custom crates tailored to the dimensions of the machine components provide an extra layer of protection, minimizing the risk of shifting or impacts during the journey;

- To further safeguard against any jostling, the use of ample padding and braces is essential, securing the machines in a stable position within the crates.

These precautions collectively serve to create a cocoon of safety around the industrial craft machines, shielding them from any potential hazards that may arise during transportation.

When enlisting the services of professional movers, it is imperative to ensure they possess the expertise and specialized equipment necessary for handling heavy machinery with precision and care. Loading and unloading such substantial equipment demands the use of appropriate machinery, such as cranes or forklifts, to ensure a safe and smooth transfer onto and off the transport vehicles. Meticulous planning and coordination by the professional moving team are crucial to execute these maneuvers flawlessly, guaranteeing the integrity of the machines remains intact throughout the loading and unloading processes. By entrusting the task to experienced movers equipped with the right tools, you can rest assured that your industrial craft machines are in capable hands, and their journey to the new location will be conducted with the highest degree of professionalism and safety.

Protecting Sensitive Components

The intricate nature of industrial craft machines demands special attention to safeguard their delicate electronic components and precision parts throughout the relocation process. These machines are susceptible to damage from various factors, such as shocks, vibrations, and dust, which can compromise their functionality and performance. To ensure their utmost protection, it is crucial to implement extra precautions during the move.

- Employ anti-static materials during the packing process. These specialized materials are designed to prevent static electricity buildup, which can be detrimental to sensitive electronic components. By carefully wrapping these components in anti-static materials, you create a protective barrier that shields them from any potential electrical discharge, reducing the risk of damage caused by electrostatic events;

- Cushioning plays a vital role in maintaining the integrity of the industrial craft machines. Strategically placing cushioning materials, such as foam or bubble wrap, around delicate components helps absorb shocks and vibrations that may occur during transportation. This cushioning acts as a buffer, reducing the impact forces that could otherwise lead to component damage. Properly cushioned packaging ensures that even if the machines encounter rough handling or encounter bumpy roads during transit, their sensitive elements remain shielded from harm;

- Protecting the machines from dust is equally crucial, as accumulated dust particles can infiltrate and disrupt the intricate mechanisms within the equipment. Sealing the components and the entire machine in dust-resistant packaging ensures that no external particles can compromise their functionality. This step is especially significant if the relocation involves a long-distance move, where the machines might be exposed to different environments along the way.

Efficiently Transporting the Machines

Coordinate the transportation logistics meticulously to minimize transit time and any potential delays. Consider factors such as road conditions, permits, and travel restrictions, especially if the move involves interstate or international routes.

Tips on how to efficiently transport the machines:

- Plan Ahead: Start the transportation process well in advance, allowing ample time for preparation, coordination, and addressing any potential challenges that may arise;

- Conduct Equipment Inspection: Thoroughly inspect all machines before transportation to identify any existing issues or vulnerabilities. Addressing these concerns beforehand ensures that the machines are in optimal condition for the move;

- Choose the Right Transport Method: Select a transportation method that suits the size, weight, and sensitivity of the machines. Options include flatbed trucks, enclosed trailers, or specialized carriers equipped for heavy machinery;

- Secure Necessary Permits: If the move involves interstate or international transportation, obtain all the required permits and clearances in advance to avoid delays at checkpoints;

- Coordinate with Professional Movers: If feasible, hire experienced industrial machinery movers with a track record of handling similar equipment relocations. Their expertise ensures a smooth and safe transportation process;

- Use Custom Crates and Packaging: Create custom crates and packaging tailored to fit each machine precisely. Secure the components within the crates using padding, braces, and anti-static materials to protect against shocks and vibrations;

- Label and Document Components: Label each component during disassembly and document the process through photos or videos. These records serve as valuable references during reassembly;

- Ensure Insurance Coverage: Confirm that the transportation company or professional movers have appropriate insurance coverage for potential damages during transit;

- Optimize Route Planning: Plan the most efficient route, taking into account road conditions, traffic, and potential construction zones. Avoid routes with low clearance or weight restrictions;

- Coordinate with Authorities: Inform local authorities about the transportation of oversized equipment, and coordinate with them to manage traffic and potential road closures;

- Communicate with the Destination Site: Keep the receiving team at the destination site informed about the expected arrival time and any special requirements for unloading and installation;

- Perform Test Runs: For international transportation or long-distance moves, conduct test runs on a smaller scale to identify potential issues and optimize the transportation process;

- Secure Machinery during Transit: Double-check that all machines are securely fastened and immobilized during transportation to prevent shifting or damage;

- Monitor Weather Conditions: Keep an eye on weather forecasts and be prepared for any adverse conditions that may affect transportation;

- Prepare Contingency Plans: Have contingency plans in place for unexpected delays, alternative routes, or emergency situations during transportation.

Safely Reassembling and Testing

Upon the arrival of the machines at their new location, the focus shifts to the meticulous reassembly process, drawing on the detailed records of the disassembly. Employing utmost care and precision, the reassembly team methodically puts together each component, ensuring they fit seamlessly as intended. The recorded disassembly process serves as a valuable guide, facilitating a streamlined and efficient reassembly procedure. Throughout this phase, the team remains vigilant, double-checking every connection and alignment to guarantee that the machines are restored to their optimal state.

Once the reassembly is complete, a comprehensive series of tests are conducted to evaluate the functionality of each component. These tests serve as a vital quality assurance measure, verifying that every part is operating correctly and cohesively. Any deviations or discrepancies are promptly addressed and resolved to guarantee the machines’ smooth operation. Rigorous testing ensures that the machines are in peak condition, ready to resume production activities with the same level of reliability and precision as before the relocation.

Conclusion

Moving industrial craft machines, especially CNC machines, requires careful planning, expertise, and attention to detail. By following this comprehensive guide, you can navigate the relocation process smoothly, minimizing downtime and ensuring the safety and integrity of your valuable equipment. Remember, seeking professional assistance and meticulously adhering to safety guidelines will result in a successful move that protects your investment and keeps your operations running smoothly.