When it comes to woodworking or metalworking projects, a lathe is an indispensable tool. Whether you’re a hobbyist or a professional, finding the right lathe within your budget is crucial.

Introduction: Navigating the Cost of Lathes

When it comes to woodworking or metalworking, the decision to invest in a lathe can significantly impact your craft and budget. Understanding the costs associated with purchasing a lathe is crucial for both hobbyists and professionals. The question of how much lathes cost is not just about the initial price tag; it encompasses a range of factors including the type of lathe, its features, durability, and the potential for future upgrades. This guide aims to provide a comprehensive overview of lathe costs, helping you make an informed decision that aligns with both youre crafting needs and financial considerations. Whether you’re exploring options for a compact mini lathe for your garage workshop or considering a high-precision CNC lathe for professional use, navigating through the complexities of lathes cost is vital in choosing the right tool that offers both quality and value.

Types of Lathes

Wood Lathes

Wood lathes are designed for woodworking enthusiasts, allowing them to craft beautiful pieces from various types of wood. These lathes come in different sizes, with features ranging from basic to advanced, impacting their cost.

Metal Lathes

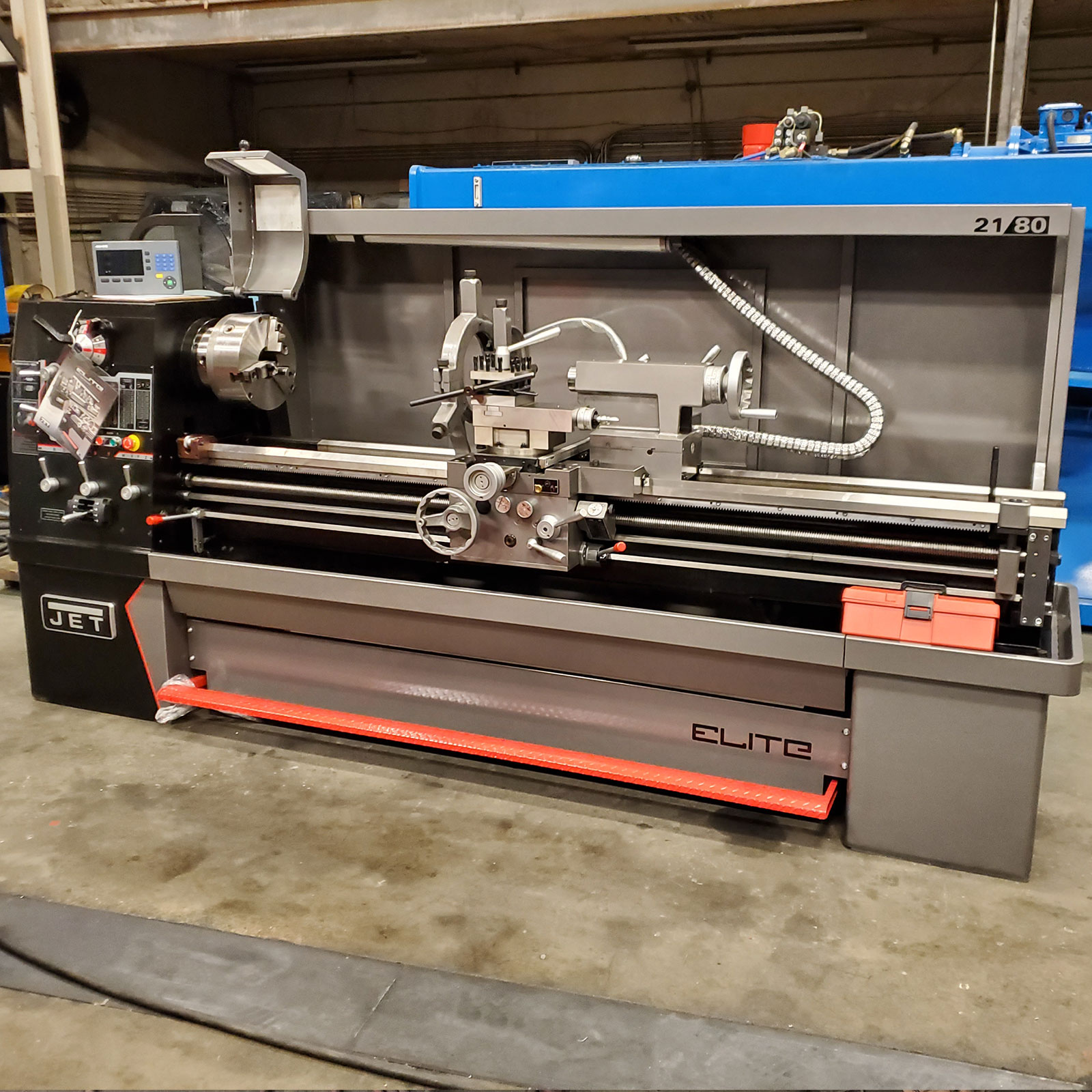

Metal lathes are engineered for precision metalworking. They are more robust and equipped with features such as threading capabilities and automatic feed systems, making them ideal for machining metal components.

Mini Lathes

Mini lathes are compact and portable versions of their larger counterparts. These lathes are perfect for small-scale projects and hobbyists with limited space. Their affordability often makes them an attractive option.

CNC Lathes

CNC (Computer Numerical Control) lathes are the epitome of modern engineering. These automated machines offer unparalleled precision and versatility, but they come with a higher price tag due to their advanced technology.

Factors Influencing Lathe Costs

Size and Capacity

Lathes are available in various sizes, and their costs tend to increase with larger capacities. Consider the scale of your projects and choose a lathe that can handle the workloads you anticipate.

Power and Motor Strength

The power and motor strength of a lathe influence its performance and price. High-powered lathes are better suited for heavy-duty work but may cost more.

Bed Construction and Material

Lathes with sturdy and durable bed constructions usually command higher prices. Cast iron beds, for instance, offer excellent stability but might be costlier than other materials.

Speed Range and Adjustability

Lathes with variable speed options are more versatile, allowing you to work with different materials. Such adjustability may impact the overall cost.

Brand and Reputation

Reputable brands often offer better quality lathes, but they may also come with a higher price. However, investing in a trusted brand can lead to increased longevity and performance.

Cost Comparison of Popular Lathes

To provide a clearer understanding of the cost range, let’s compare four popular lathes:

| Lathe Model | Type | Price Range ($) | Key Features |

|---|---|---|---|

| Woodlathe 1000 | Wood Lathe | $500 – $800 | 14-inch swing, 40-inch between centers |

| PrecisionMaster 750 | Metal Lathe | $1,200 – $2,000 | 1 HP motor, 18-inch distance between centers |

| MiniTurn GT10 | Mini Lathe | $300 – $500 | 10-inch swing, portable and compact |

| CNCPro 2000 | CNC Lathe | $5,000 – $10,000 | Computer-controlled, high precision |

Tips for Finding the Best Deals

- Research Online: Compare prices from different suppliers and check for any ongoing promotions or discounts;

- Consider Used Lathes: If budget is a concern, explore the option of purchasing a quality used lathe. Many used lathes are in excellent condition and can save you money;

- Bundle Deals: Some suppliers offer bundle deals with accessories included. Assess the value of the package to see if it fits your requirements;

- Read Reviews: Look for reviews from other lathe users to gauge the performance and durability of the model you’re interested in.

Lathe Accessories and Additional Costs

While the lathe itself is a crucial investment, there are also various accessories and additional costs to consider. These accessories can enhance your lathe’s capabilities and improve your overall woodworking or metalworking experience. Some common accessories include:

Lathe Chucks:

Lathe chucks are essential for holding workpieces securely in place. They come in different sizes and styles, and the cost varies accordingly.

Cutting Tools:

Different cutting tools are required for various lathe operations. Investing in high-quality tools can improve precision and reduce wear, but it adds to the initial cost.

Tool Rests:

Tool rests provide support for cutting tools and help maintain consistent angles during turning. They are available in various lengths and can be an add-on expense.

Lathe Stand or Bench:

If your lathe doesn’t come with a stand, you’ll need to purchase one separately or build a stable workbench to support the lathe.

Warranties and After-Sales Support

When purchasing a lathe, it’s essential to consider the warranty and after-sales support provided by the manufacturer or supplier. A comprehensive warranty can offer peace of mind, protecting you against manufacturing defects and malfunctions. Additionally, look for suppliers that offer excellent customer service, technical assistance, and readily available spare parts.

Factors Affecting Second-Hand Lathe Prices

For budget-conscious buyers, second-hand lathes can be an attractive option. However, the prices of used lathes are influenced by several factors, including:

Age and Condition:

Older lathes may be more affordable, but their condition and wear must be carefully assessed before making a purchase.

Brand and Model:

Some older models from reputable brands retain their value well, even in the used market.

Upgrades and Modifications:

Lathes with added features or recent upgrades may command higher prices.

Seller Reputation:

Buying from a trusted seller can ensure a smoother transaction and a fair price.

Making an Informed Decision: Factors vs. Budget

Ultimately, the ideal lathe for you will depend on striking a balance between your budget and the essential factors that meet your needs. It’s crucial to evaluate your requirements and prioritize the features that matter most for your projects. Consider what you can afford while keeping in mind that a reliable, quality lathe can be a valuable long-term investment. Don’t compromise on essential features, but also avoid overextending your budget if unnecessary.

Budgeting Tips and Financing Options

Investing in a lathe can be a significant financial commitment, but there are several budgeting tips and financing options to make the purchase more manageable.

Set a Budget:

Determine how much you’re willing to spend on a lathe and stick to that budget. Research the average prices of lathes that meet your requirements to set a realistic budget.

Consider Financing:

Many suppliers offer financing options that allow you to spread the cost over several months. Carefully review the terms and interest rates before committing to any financing agreement.

Save on Other Woodworking or Metalworking Tools:

If your budget is limited, consider prioritizing the lathe purchase and saving on other tools initially. You can gradually acquire additional tools as needed.

Explore Local Deals and Discounts:

Check for local woodworking or metalworking clubs, as they might have group discounts or access to used lathes at more affordable prices.

Maintenance and Care Tips for Your Lathe

To ensure the longevity and optimal performance of your lathe, proper maintenance and care are essential. Follow these maintenance tips to keep your lathe in top condition:

1. Regular Cleaning:

Clean your lathe after each use to remove dust, debris, and metal shavings. A clean lathe operates more smoothly and prevents premature wear.

2. Lubrication:

Follow the manufacturer’s guidelines for lubricating moving parts regularly. Proper lubrication reduces friction and enhances precision.

3. Belt and Motor Inspection:

Check the belts and motor regularly for signs of wear or damage. Replace them as needed to avoid potential accidents and ensure consistent performance.

4. Storage:

If you won’t be using the lathe for an extended period, store it in a clean and dry environment, preferably covered to protect it from dust and moisture.

Upgrading and Expanding Your Lathe Setup

As you gain experience and take on more ambitious projects, you may find the need to upgrade or expand your lathe setup. Here are some options to consider:

Attachments and Accessories:

Explore additional attachments and accessories to expand your lathe’s capabilities. Some examples include indexing attachments, steady rests, and specialized chucks.

Adding a Lathe Extension:

If your current lathe is limited in capacity, consider adding a lathe extension to increase the distance between centers and accommodate larger workpieces.

CNC Conversion:

For those with mechanical and technical expertise, converting a manual lathe to CNC can be a rewarding project. This upgrade allows for computer-controlled precision and opens up a world of possibilities.

Upgrading to a Larger Model:

If your projects consistently exceed your lathe’s capacity, consider upgrading to a larger, more powerful model that can handle more substantial workloads.

Conclusion

Investing in a lathe is a significant decision, and its cost depends on various factors, including type, size, features, and brand reputation. By considering these factors and comparing different options, you can find a lathe that perfectly suits your needs and budget.