If you’re a machinist or CNC expert familiar with vertical mills, you must undoubtedly be well-acquainted with the remarkable lathe machine. Despite the modern advancements and cutting-edge technologies in today’s lathe machines, it might surprise you to learn that they have a fascinating history dating back to ancient Egypt around 1300 BCE.

During the 16th century C.E., lathe machines gained significant prominence in France, primarily utilized for crafting wooden products. However, it was the Industrial Revolution in the 18th century that marked a turning point, as the people of England revolutionized the lathe, leading to the modernization of the metal lathe.

Lathes are powerful and versatile machines that have been used for centuries in various industries. These impressive tools are designed to rotate a workpiece on its axis while cutting, shaping, drilling, or sanding it with precision and control. From traditional crafts to modern manufacturing processes, lathes have remained an indispensable part of workshops and factories worldwide. In this article, we will explore the myriad applications of lathes and understand why they continue to play a vital role in shaping the world around us.

Understanding Lathes: A Versatile Machining Tool

A lathe, a versatile machining tool, finds primary application in shaping both metal and wood. The core principle involves rotating the workpiece while a stationary cutting tool shapes it, resulting in precisely crafted workpieces.

Lathes come in various types, each specialized for specific materials and techniques. At All Metals Fabricating, we offer four distinct lathe types, including one with live tooling capabilities for multitasking tasks.

From fabricating machinery parts to creating artistic bowls and musical instruments, lathes have a wide array of applications. Regardless of their type, all lathes rely on the fundamental concept of holding and rotating the workpiece to achieve remarkable results.

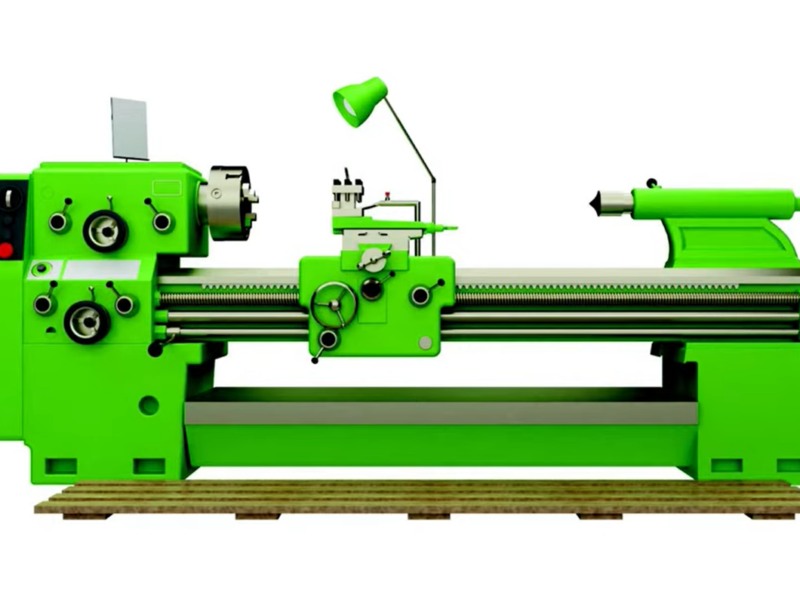

Anatomy of a Lathe: Essential Components and Functionality

A lathe comprises several key parts that work together to facilitate its machining capabilities. Let’s delve into each component:

| Component | Function |

|---|---|

| The Bed | Provides the foundation and support for all lathe parts. Determines the maximum diameter limit of the workpiece. |

| Proper Orientation | Ensures correct positioning of headstock on the left and tailstock on the right for efficient lathe operation. |

| The Headstock | The central part of the lathe, applies power to the workpiece through the motor, and houses the main spindle. |

| The Motor | Located underneath the lathe bed, drives the lathe’s operations using either electric or hydraulic power. |

| Adjustable Parts | The toolrest can be adjusted for height and rotation to achieve precision, ensuring modifications are made safely. |

| Tailstock Flexibility | Tailstock is adjustable and removable, adding versatility to lathe work, and adjustments should be made when off. |

| Attachments and Accessories | Spindles accommodate various attachments like centers, chucks, and faceplates, aiding in workpiece positioning. |

The Lathe Machine Working Process

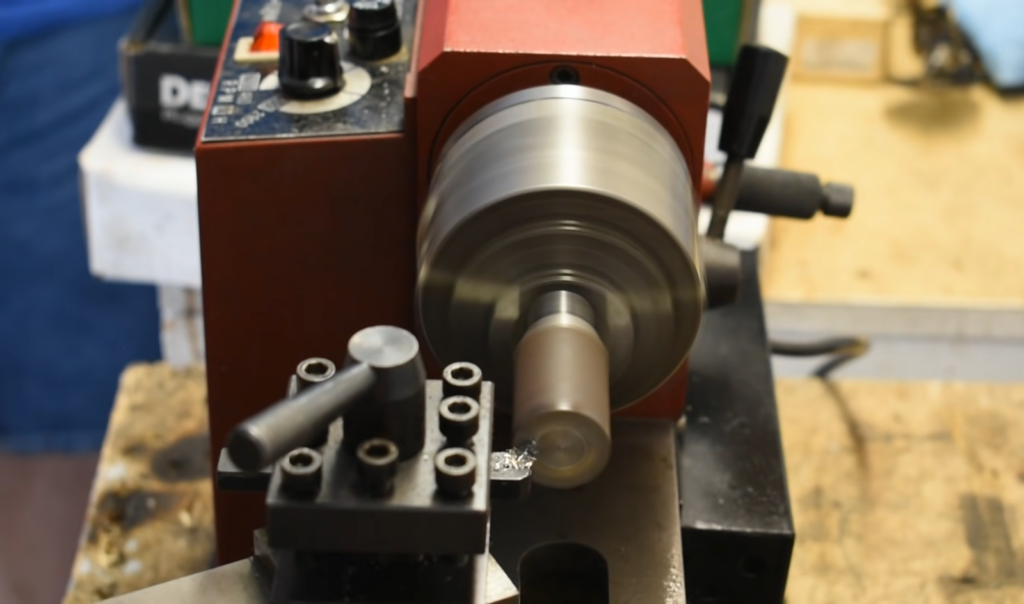

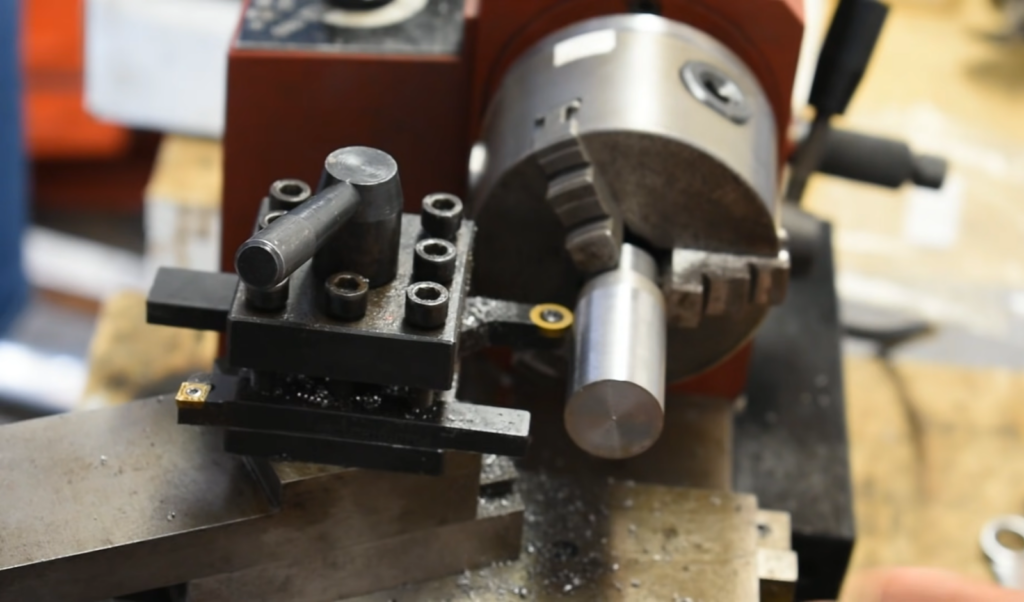

Step 1: Positioning the Workpiece

The workpiece is securely placed between the headstock and tailstock of the lathe machine. It is firmly held in place using a chuck, which grips the workpiece from the outside and ensures stability.

Step 2: Initiating Rotation

To facilitate machining, the workpiece is set into motion by the spindle, connected to a motor. The spindle causes the workpiece to rotate around its axis.

Step 3: Introducing the Cutting Tool

A cutting tool is carefully positioned in the tool holder, maintaining an appropriate distance from the rotating workpiece. The tool’s blades are aligned to cut the workpiece as desired. Depending on the desired shapes and materials, various types of cutting tools are utilized.

Types of Lathe Machines

In the contemporary world, a diverse range of lathe machines caters to various industrial and creative needs. Some widely used types include:

| Type of Lathe | Description | Main Application |

|---|---|---|

| Engine Lathe | Enduring invention from the Industrial Revolution, initially powered by steam engines. | Industries for metal drilling and boring. |

| Speed Lathes | Designed for cutting wood, known for their high spindle revolution velocity. | Woodworking for turning wooden pieces. |

| Turret Lathes | Ideal for producing identical workpieces, equipped with a turret for multiple cutting tools. | Mass production of consistent parts. |

| Tool Room Lathes | Preferred choice for precision cuts, offering precise control over cutting speeds. | Precision machining and engineering applications. |

| Glass Lathes | Handles delicate glassware, uses heat from a torch to make glass malleable for shaping by hand. | Crafting glassware and decorative items. |

Comparing Metal Work Lathes and Wooden Work Lathes

While lathes share common functionalities, it’s important to note that not all lathes can handle every material. For instance, a lathe designed for crafting wooden products cannot be utilized for working with metal pieces. The distinction between metal work lathes and wooden work lathes lies in their specific capabilities and applications.

| Features | Metal Work Lathe | Wooden Work Lathe |

|---|---|---|

| Engine Power | Strong engine power | Relatively less powerful engine |

| Rotation Speed | Faster rotation with variable speed | Rotation speed: 500-1200 RPM |

| Size and Sharpness of Cutting Tools | Bigger-sized and more sharpened blades | Smaller-sized and less sharpened blades |

The Versatile Applications of Lathes: Who Can Benefit?

Lathes, often referred to as the “mother of machining tools,” offer a wide array of applications that make them indispensable for various industries. Their versatility allows them to excel in shaping, drilling, sanding, knurling, turning, cutting, and deformation processes. This unique combination of functionalities makes lathes a go-to tool for both metal and woodworking tasks.

Considering the diverse capabilities of lathes, they prove to be ideal for a broad range of individuals and teams:

- Metalworkers: Lathes are a staple in metalworking industries, facilitating precise shaping and cutting of metal parts, resulting in accurate components for various applications;

- Woodworkers: For crafting wooden masterpieces, lathes enable turning and shaping wood into intricate designs, from furniture to decorative items;

- Machinists: Lathes are essential in machining processes, where precision and accuracy are crucial in producing high-quality parts;

- Hobbyists: Whether you are a metal or woodworking hobbyist, lathes provide a fulfilling experience by allowing you to create customized pieces with ease;

- Engineers: In engineering and manufacturing, lathes play a vital role in fabricating prototypes, testing new designs, and achieving desired specifications;

- Artisans and Craftsmen: For artists and craftsmen, lathes unleash creativity, enabling them to transform raw materials into unique and artistic creations;

- Repair and Maintenance Technicians: Lathes aid in repairing and refurbishing worn-out or damaged parts, prolonging the life of machinery and equipment;

- Educational Institutions: Lathes serve as an essential tool in technical schools and workshops, providing students with hands-on experience in machining processes;

- Small Workshops and Large Industries: From small-scale workshops to large manufacturing plants, lathes are valuable assets for their efficiency and versatility.

Conclusion

From heavy industries to artistic crafts, lathes are indispensable tools that have stood the test of time. Their ability to shape and refine various materials with precision has made them a cornerstone in modern manufacturing and creative processes. Whether it’s turning, facing, parting, threading, or a myriad of other applications, lathes continue to play a vital role in the advancement of technology and innovation, contributing to the development of a wide range of products that enrich our daily lives.