Throughout history, mankind has undertaken a remarkable endeavor to explore and uncover the most formidable metal known to humanity, delving into the domains of chemistry, physics, and metallurgy. Tungsten is a metal that exhibits exceptional properties, distinguishing it as a leading candidate for the highest recognition among the metals currently being studied.

Characteristics of Tungsten

Tungsten, also commonly referred to as Wolfram, boasts a remarkable array of qualities. With its atomic number 74 and symbol ‘W’, this metal showcases a wide range of distinctive attributes, setting it apart as an exceptionally strong and durable element.

| Characteristics | Description | Applications |

|---|---|---|

| 1. High Tensile Strength | Among all known materials, tungsten stands unrivaled with its tensile strength measuring at 1510 MPa. Its robust atomic structure and metallic bonds bestow upon it the ability to endure significant tensile forces without any deformation or fracturing. This exceptional quality makes it highly suitable for applications demanding utmost durability. Notably, tungsten wires find extensive use in various industries, including the production of incandescent light bulb filaments and electron microscopy, owing to their remarkable tensile strength. | – Filaments for incandescent light bulbs<br>- Electron microscopy |

| 2. Exceptional Melting Point | Tungsten boasts the highest melting point among all metals, reaching an impressive 3422 degrees Celsius (6192 degrees Fahrenheit). This outstanding heat resistance makes it an ideal choice for situations requiring materials to withstand prolonged exposure to high temperatures. Key applications include rocket nozzles and aerospace components that must endure the extreme heat of space flight. | – Aerospace components<br>- Rocket nozzles |

| 3. Impressive Density | With a density of 19.3 g/cm3, tungsten takes the third spot in terms of weight, trailing behind gold and platinum. Its elevated density enhances its mechanical properties and transforms it into an effective radiation barrier. In aerospace and defense applications, tungsten-based alloys are frequently employed to increase aircraft mass and balance moving components. Moreover, its high density makes it a favorable choice for radiation shielding in clinical and manufacturing settings. | – Aerospace applications<br>- Defense applications<br>- Radiation shielding |

| 4. Excellent Hardness | When combined with other elements, like steel, tungsten exhibits even greater hardness than its inherent toughness. This exceptional toughness renders it highly resistant to bending and scratching. Its extreme hardness makes tungsten carbide a widely utilized material in various applications, including cutting tools, drill bits, and abrasives. Thanks to its remarkable hardness and consequent resistance to wear and tear, tungsten finds extensive use across diverse commercial and industrial contexts. | – Cutting tools<br>- Drill bits<br>- Abrasives |

Applications of Tungsten

Tungsten’s exceptional properties render it invaluable in numerous technological and industrial fields. Some notable applications include, but are not limited to:

- Electronics and Electrical Devices: Tungsten finds extensive use in a wide array of electronic devices due to its remarkable combination of a high melting point and excellent electrical conductivity. It serves common applications like electrical connections, X-ray tubes, and electron emitters. Additionally, tungsten wires, with their high tensile strength and heat resistance, are also employed in electronics and electrical equipment;

- Filaments for Lighting: Tungsten remains a popular choice for producing incandescent light bulb filaments. Its high melting point enables the filament to reach high temperatures without melting or deforming, thereby producing a significant amount of light. Although incandescent bulbs have largely been replaced by more efficient alternatives, tungsten continues to play a crucial role in the lighting industry;

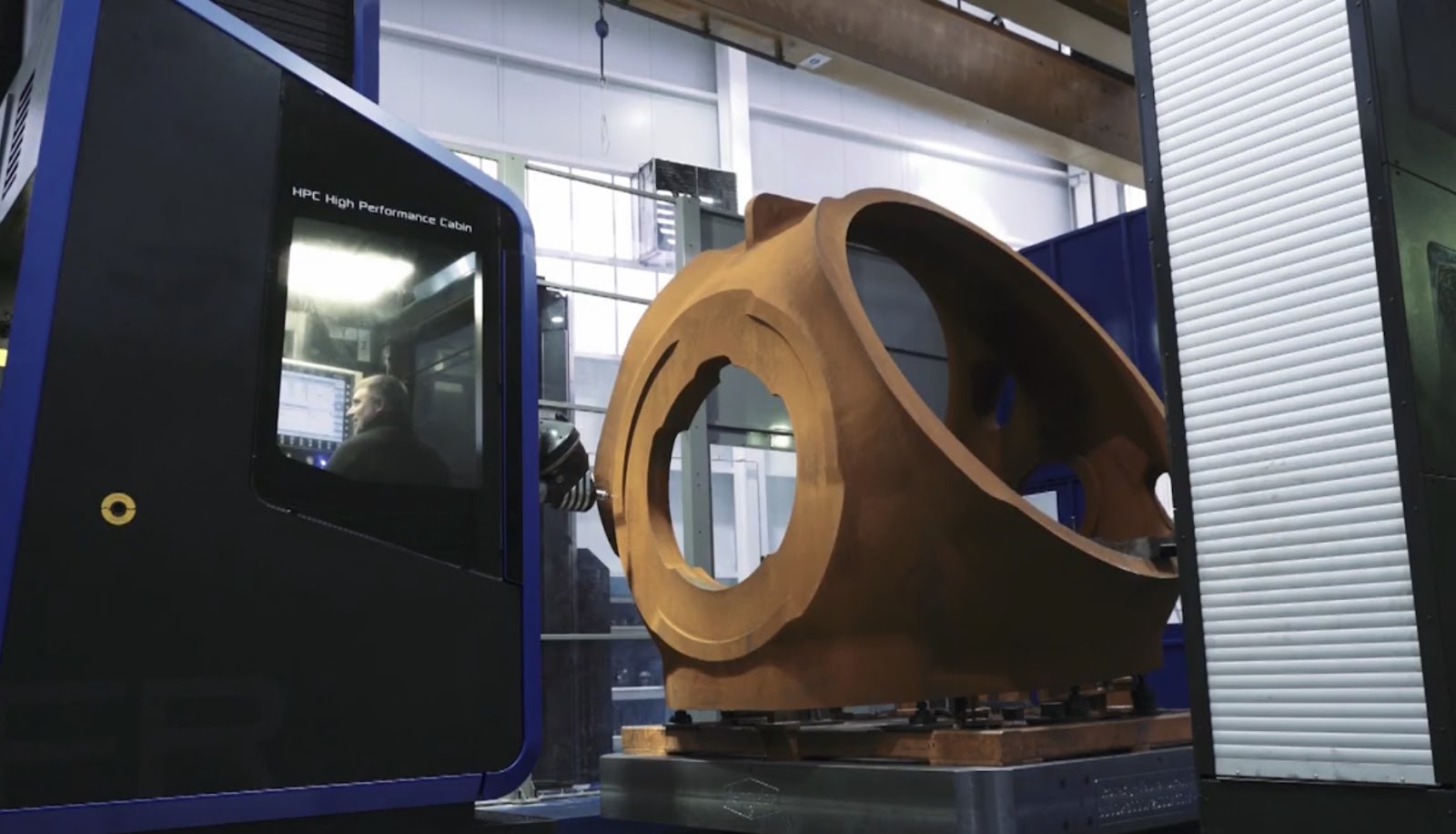

- Aerospace and Aviation: The aerospace and aviation sectors derive significant advantages from the exceptional characteristics of tungsten. Components like rocket nozzles, turbine blades, and others used in space and aviation encounter extreme conditions. Thus, tungsten’s remarkable strength, density, and heat resistance make it an ideal material for these applications;

- Medical Applications: Tungsten is widely used as a radiation shielding material in the medical industry, particularly in X-ray and gamma-ray environments. Thanks to its high density, it effectively absorbs and attenuates harmful radiation, ensuring the safety of both patients and medical personnel;

- Cutting and Machining Tools: Tungsten carbide’s hardness proves highly advantageous for various cutting tools such as saw blades, drill bits, and others. Its exceptional hardness and durability make it a common choice in cutting and machining processes that demand utmost precision;

- Defense and Military Applications: Tungsten alloys, with their high density and superior penetrability, are perfectly suited for defense applications. They find use in tank ammunition and anti-ship missiles as kinetic energy penetrators, known as APFSDS (Armor-Piercing Fin-Stabilized Discarding Sabot).

Comparison with Other Strong Metals

To grasp the remarkable strength of Tungsten, it’s beneficial to make comparisons with other resilient metals. The main analogies are as follows:

- Tungsten vs. Steel: Steel, especially high carbon and alloy steel, is renowned for its durability. Nonetheless, even in its hardest form, its tensile strength usually doesn’t exceed 3700 MPa, making it weaker than Tungsten. However, steel generally surpasses Tungsten in terms of impact strength and hardness;

- Tungsten vs. Titanium: With a tensile strength of approximately 1000 MPa, Titanium cannot compare to Tungsten. Nevertheless, aerospace and medical implant applications can still take advantage of Titanium’s lower weight and higher resistance to corrosion;

- Tungsten vs. Inconel: The superalloy Inconel is greatly prized for its exceptional capability to endure elevated temperatures and pressures. In comparison to Tungsten, Inconel exhibits higher resistance to corrosion, but its tensile strength (1034 MPa) is comparatively lower.

Practical Applications of Tungsten

Tungsten’s high strength and low heat conductivity make it applicable in a wide range of contexts.

- Military Applications: Because of its exceptional density, tungsten is an excellent material for crafting heavy, armor-piercing munitions;

- Aerospace Industry: Tungsten’s high melting point makes it a fitting choice for high-temperature applications, such as in rocket engine nozzles;

- Electronics: Light bulb filaments and vacuum tube components can take advantage of tungsten’s high electrical conductivity and low thermal expansion.

Watch this video to learn more about the characteristics and uses of tungsten:

Conclusion

Tungsten is considered the strongest metal due to its exceptional attributes, such as high specific gravity and a remarkable melting point. Its strength and heat resistance surpass those of other metals, although each metal may have its distinct advantages. Tungsten’s widespread application in various industries confirms its significance as one of the remarkable achievements of metalworking.

FAQ

Due to its inherent brittleness, Tungsten is often utilized in alloy form to enhance its workability and toughness. These alloys commonly consist of a combination of Tungsten, Nickel, and Iron or Copper. By blending Tungsten with these elements, the resulting alloys achieve a balance of strength and resilience, making them more practical and versatile for various industrial applications.

Despite its impressive attributes, Tungsten is brittle and susceptible to fracturing under sudden impacts. Additionally, it is relatively expensive compared to more common metals like steel and aluminum. These factors influence its selective use in specific applications where its unique properties outweigh the limitations and cost considerations.

The high melting point of Tungsten can be attributed to the robust metallic bonds in its atomic structure, which demand a significant amount of energy to break. These strong bonds enable Tungsten to withstand extremely high temperatures without undergoing melting, making it a valuable material for various high-temperature applications.

The high melting point of Tungsten can be attributed to the robust metallic bonds in its atomic structure, which demand a significant amount of energy to break. These strong bonds enable Tungsten to withstand extremely high temperatures without undergoing melting, making it a valuable material for various high-temperature applications.