The carousel lathe, a marvel of modern engineering, stands as a testament to technological advancement in the world of metalworking. Predominantly used for heavy-duty machining, this behemoth plays a pivotal role in shaping large, cumbersome workpieces with unparalleled precision.

The Anatomy of a Carousel Lathe

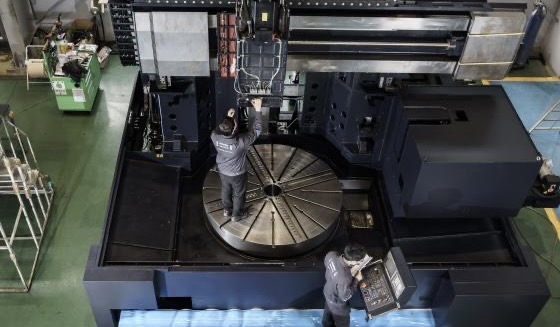

At the heart of the carousel lathe’s design lies its robust and dependable structure, a true marvel of engineering. Central to its functionality is the sturdy, rotating table. This table isn’t just a mere component; it’s a powerhouse capable of handling immense weights, often in the range of several tons. Surrounding this table are various tool heads, each meticulously engineered to perform specific tasks. These include tools for carving, cutting, and shaping metal with precision that borders on the artistic. The anatomy of a carousel lathe can be summarized as follows:

- Rotating Table: Supports and rotates the workpiece;

- Tool Heads: A variety of tools for different machining operations;

- Control Panel: For programming and controlling the lathe’s operations;

- Support Structure: Ensures stability and rigidity during heavy-duty machining.

The Working Mechanism Explained

The operational mechanism of a carousel lathe is a symphony of mechanical and technical precision. Workpieces, often large and unwieldy, are mounted onto the rotating table. Once in place, they are subjected to a carousel of cutting tools. Each tool moves in perfect harmony, orchestrated by advanced computer controls. This allows the lathe to perform a plethora of complex tasks including drilling, turning, and milling. The key lies in its ability to maintain precision while handling large-scale workpieces – a feat that is nothing short of engineering genius.

Types of Carousel Lathes

Carousel lathes are broadly categorized into two types:

- Vertical Carousel Lathes: Known for their space-efficient design, these are ideal for machining taller workpieces. Their vertical orientation means they occupy less floor space, making them suitable for smaller workshops;

- Horizontal Carousel Lathes: These are tailored for broader and heavier workpieces. The horizontal layout allows for easier handling and processing of large, heavy objects, providing a different approach to machining.

Carousel Lathe vs. Conventional Lathe: A Comparative Study

The debate between carousel and conventional lathes often centers on their capacity and versatility. Carousel lathes excel in handling larger workpieces and performing multiple operations simultaneously. This is in stark contrast to standard lathes, which might struggle with such tasks. A comparison table might look like this:

| Feature | Carousel Lathe | Conventional Lathe |

|---|---|---|

| Workpiece Size | Large | Smaller |

| Operations | Multi-tasking | Single-tasking |

| Precision | High | Moderate |

| Space Efficiency | Moderate | High |

Applications and Industries Benefiting from Carousel Lathes

Carousel lathes are not just machines; they are vital tools in various industries where precision and scale are paramount. They are especially critical in:

- Aerospace: For parts like turbines and fuselages;

- Shipbuilding: In constructing large ship components;

- Heavy Machinery: For producing large gears and flanges.

In each of these industries, the carousel lathe’s ability to shape large components with precision is invaluable.

Selecting the Right Carousel Lathe: Key Considerations

When embarking on the journey to select the perfect carousel lathe for your needs, several key considerations come into play.

Size Capacity

The foremost aspect to consider is the size capacity of the lathe. This factor is crucial as it determines whether the lathe can accommodate the dimensions of your workpieces. The size capacity needs to match the typical size of materials you plan to work with, ensuring seamless operations.

Power

The power of the lathe is another pivotal element. The machine’s power should align with your specific machining requirements. It’s essential to evaluate the nature of your projects to determine the required power level, ensuring that the lathe can efficiently handle your machining tasks.

Tooling Options

The availability and versatility of tool heads are also critical. A carousel lathe with a wide range of tooling options provides greater flexibility and allows for a broader spectrum of machining operations. This adaptability is key in choosing a machine that can meet various machining demands.

Understanding these aspects is vital in making an informed decision that aligns with your machining requirements.

Maintenance and Safety Protocols

Maintaining a carousel lathe is a task that demands attention and regularity. This maintenance is not only about preserving the machine’s functionality but also about ensuring the safety of its operators.

Regular Lubrication

One of the primary maintenance activities is regular lubrication. This practice is essential for the smooth operation of the lathe, helping to minimize friction and wear in its moving parts.

Routine Inspections

Another crucial aspect of maintenance is conducting routine inspections. These inspections are aimed at identifying any signs of wear and tear, ensuring that all components of the lathe are in good working condition.

Adherence to Safety Protocols

Strict adherence to safety protocols is a non-negotiable aspect of operating a carousel lathe. These protocols are designed to protect the operators and should be rigorously followed to prevent accidents and ensure a safe working environment.

This meticulous approach to maintenance not only ensures the machine’s longevity but also safeguards those operating it.

Innovations and Future Prospects

The future of carousel lathes is marked by optimism, thanks to the continuous advancements in technology.

Advancements in CNC and Automation

Technological developments, particularly in CNC (Computer Numerical Control) and automation, are set to significantly enhance the capabilities of carousel lathes. These advancements promise to bring about greater precision, efficiency, and versatility in metalworking.

New Possibilities in Manufacturing

Such innovations open up exciting new possibilities in the field of manufacturing. They herald a future where carousel lathes are not just tools of production but enablers of innovative and complex designs.

Carousel Lathes: Real-

world Case Studies

The real-world applications of carousel lathes serve as a testament to their importance and versatility.

In Shipbuilding

In the shipbuilding industry, carousel lathes have played a crucial role in constructing massive components. These components, essential to the structure of modern vessels, showcase the lathe’s ability to handle large-scale, precision-dependent tasks.

In Aerospace

Similarly, in the aerospace sector, carousel lathes are instrumental in fabricating intricate parts. These parts, adhering to the highest standards of precision and quality, underscore the lathe’s capability in handling complex and critical manufacturing processes.

These case studies not only demonstrate the utility of carousel lathes but also highlight their indispensable role in various industrial applications.

Conclusion

In sum, the carousel lathe is not just a machine; it’s a cornerstone in the edifice of modern manufacturing. Its ability to transform hefty metal pieces into precise components underscores its importance across various industries.