For those without background knowledge, exploring the realm of bolt sizes can be overwhelming. Nevertheless, it is a vital aspect of numerous industries, including building, engineering, and production. We have dedicated our efforts to offer a comprehensive analysis of bolt diameters, accompanied by visual representations for better understanding. Moreover, for visual learners, a helpful film awaits at the end of this inquiry. Let’s embark on this educational journey right away.

A Primer on Bolt Sizes

The construction, automotive, and industrial industries, among others, heavily rely on bolts. To select the appropriate fastener for a specific task, it is essential to be familiar with the various bolt sizes available. Understanding bolt sizes is fundamental in ensuring the safety, reliability, and efficiency of projects and applications in these industries.

Components of a Bolt

let’s take a step back from bolt sizes and explore what constitutes a standard bolt.

- Head: The head, positioned at the top of the bolt, is designed for easy gripping with minimal effort. Bolts are available in two common head shapes: hexagonal (hex) and circular (round head). These head designs allow for convenient use with appropriate tools such as wrenches or sockets, enabling efficient tightening and loosening during installation or removal processes;

- Shank: The shank of a bolt is its central part that connects the head to the threads. It is typically unthreaded and serves as a solid base for the bolt. The unthreaded shank provides stability and strength to the fastening, making it essential for securely holding components together in various applications;

- Thread: The shank of the bolt features a spiral-shaped groove known as the thread. This thread is the part of the bolt that is intended to be screwed into a nut or the corresponding hole in the complementary material.

Bolt Size Terminology

The following dimensions are used to define a bolt’s size:

- Diameter: The bolt’s shank thickness is what the diameter measures. The diameter of a bolt is measured in millimetres (mm) in the metric system. The shank diameter of an M6 bolt, for instance, is 6mm;

- Thread Pitch: The bolt’s thread pitch specifies how far apart threads are. Millimetres are the metric system’s standard for measuring this. A bolt designated as M6x1 has a 1mm thread pitch, for instance;

- Length: The bolt’s length is the shank’s length expressed in millimetres. The shank length of an M6x1x20 bolt, for instance, is 20mm.

Metric Bolt Sizes

Metric bolts are standard worldwide and are named according to the metric system. Standard metric bolt sizes range from M4 to M20, with the latter two being the least frequent. The diameter range of certain frequently used metric bolts is summarized in the table below.

| Bolt Size (Metric) | Diameter (mm) |

|---|---|

| M4 | 4 |

| M5 | 5 |

| M6 | 6 |

| M8 | 8 |

| M10 | 10 |

| M12 | 12 |

| M16 | 16 |

| M20 | 20 |

Understanding Bolt Sizing Notation

Learning the notation used to describe bolt sizes is essential for working with them. Take the M6x1x20 standard as an illustration:

- M6: This means the diameter of the bolt is 6 mm;

- 1: In this situation, 1 denotes a thread pitch of 1 millimetre. It’s a visual representation of the space between two parallel threads;

- 20: In this case, 20mm is the length of the bolt being discussed.

Common Bolt Types

There are many varieties of bolts, each with its own set of advantages and uses. The following are examples of common kinds of bolts:

- Hex Bolts (Hex Head Bolts): Hexagonal-headed bolts, or “hex bolts,” require only a wrench to tighten or loosen. They have several uses in the building, manufacturing, and automobile industries;

- Carriage Bolts: Carriage bolts have a square portion underneath their circular head. They are commonly employed with wooden structures or in situations calling for a flawless finish;

- Allen Bolts (Socket Head Bolts): Allen bolts are distinguished by their hexagonal socket inside a cylinder-shaped head. Common in industry and electronics, they require an Allen wrench for tightening;

- Eye Bolts: Eye bolts are fasteners with a looped head, ideal for using wherever ropes or cables must be fastened firmly.

Factors to Consider When Choosing Bolts

To ensure best performance and safety, it is important to select the proper bolt for the job. Some essential things to keep in mind are:

- Load and Strength Requirements: Calculate the needed strength and load bearing capacity. Picking a strong enough bolt guarantees dependability and security;

- Environmental Conditions: Think about the weather, temperature swings, and potential corrosives that the bolt will be subjected to in its surroundings. Bolts made of stainless steel or galvanized steel are resistant to corrosion even in severe conditions;

- Material Compatibility: To avoid galvanic corrosion, check that the bolt material is compatible with the other materials it will be touching;

- Thread Engagement: When using bolts to secure many parts together, be sure there is sufficient thread engagement to generate sufficient clamping force.

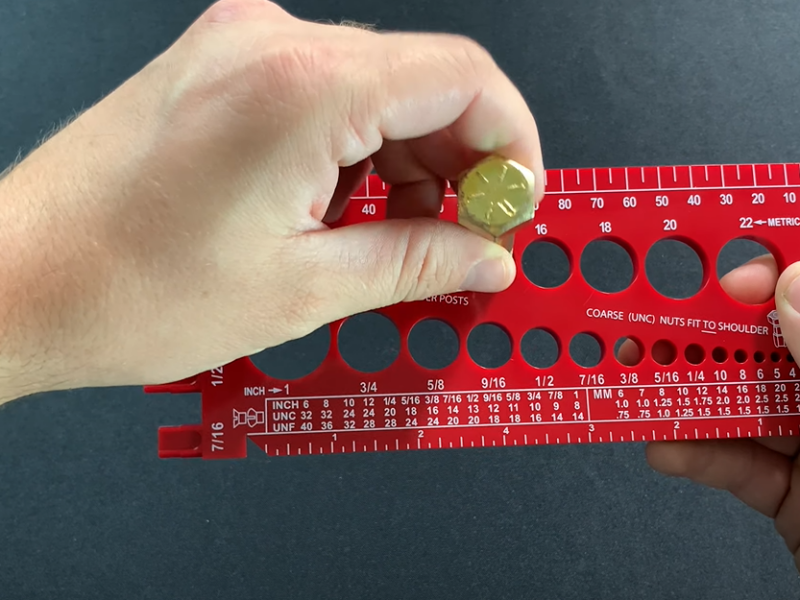

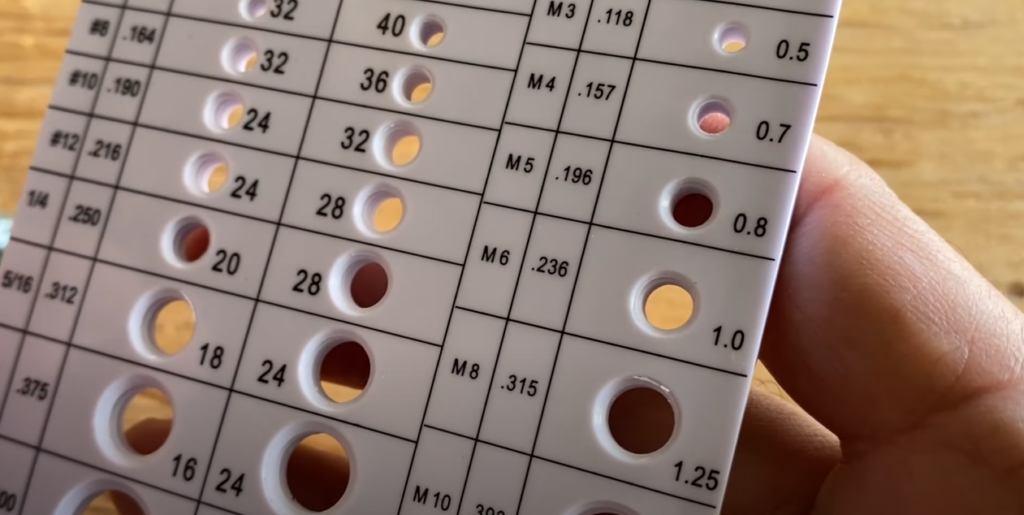

Bolt Size Chart

It is helpful to have a chart to reference when looking for a specific size of bolt. Check out this simplified metric bolt size chart:

| Bolt Size (M) | Diameter (mm) | Thread Pitch (mm) | Length (mm) |

|---|---|---|---|

| M6 | 6 | 1 | 20 |

| M8 | 8 | 1.25 | 30 |

| M10 | 10 | 1.5 | 40 |

| M12 | 12 | 1.75 | 50 |

Keep in mind that this table just serves as an example of the large range of bolt lengths available.

Understanding Imperial Bolt Sizes

The United States often uses the imperial system when referring to bolt sizes. Imperial bolt sizes are not as simple as the metric system, with fractions representing the bolt diameter and the thread pitch expressed as the number of threads per inch (TPI).

Imperial Bolt Size Representation

In the imperial system, the diameter of a bolt is expressed as a fraction to indicate its size. Threads per inch (TPI) is a measurement of the thread pitch. A 1/4-20 bolt, for instance, has both a 1/4-inch diameter and 20 threads per inch.

Let’s examine the components that make up the imperial bolt sizes:

- Diameter: A fraction of an inch is used to denote the diameter of an imperial bolt. Common sizes are 1/4 inch, 5/16 inch, 3/8 inch, and 1/2 inch;

- Thread Pitch: Threads are measured in terms of their pitch, which is expressed in terms of TPI. The space between two threads is represented here. A 1/4-inch-twenty bolt, for instance, has twenty threads per inch;

- Length: Inches are the standard unit of measurement for imperial bolt length. It is the bolt’s shank measurement. The shank length of a 1/4-20×1 bolt, for instance, is 1 inch.

Imperial Bolt Size Chart

Common imperial bolt sizes and their corresponding diameter, thread pitch, and length are listed in the following table.

| Bolt Size | Diameter (inch) | Thread Pitch (TPI) | Length (inch) |

|---|---|---|---|

| 1/4-20 | 1/4 | 20 | 1 |

| 5/16-18 | 5/16 | 18 | 1.5 |

| 3/8-16 | 3/8 | 16 | 2 |

| 1/2-13 | 1/2 | 13 | 2.5 |

Understanding the chart

- A 1/4-20 bolt has a 1/4-inch diameter with 20 threads per inch and is available in a 1-inch length;

- A 5/16-18 bolt has a 5/16-inch diameter with 18 threads per inch and is available in a 1.5-inch length;

- A 3/8-16 bolt has a 3/8-inch diameter with 16 threads per inch and is available in a 2-inch length;

- A 1/2-13 bolt has a 1/2-inch diameter with 13 threads per inch and is available in a 2.5-inch length.

Factors to Consider When Using Imperial Bolts

To guarantee appropriate application and reliability while working with imperial bolt sizes, a number of parameters must be carefully considered. Some crucial considerations include:

- Compatibility: Check to see that the components you’re linking use the same size imperial bolts. The bolt, nut, and threaded hole all need to have their thread size and pitch examined;

- Material: Bolts must be made from the appropriate material for the intended use. Steel, stainless steel, and brass are the most typical materials for imperial bolts;

- Strength and Load: Think about the project’s load needs, and pick bolts that are strong enough to withstand those loads;

- Length: It is important to take the time to calculate the exact length of the bolt needed for the job. The length of the bolt must be adequate to ensure adequate thread engagement without bottoming out;

- Corrosion Resistance: Bolts with corrosion-resistant coatings or materials should be used in outdoor or corrosive situations;

- Torque Specifications: The joint’s integrity can be compromised if the bolts are either over- or under-tightened, thus it’s important to follow the appropriate torque specifications.

Advantages of Imperial Bolt Sizes

While the metric system is more common, there are benefits to using imperial bolt sizes in areas where that is the norm:

- Familiarity: Workers and professionals in the United States and other nations that utilize the imperial system are more likely to be familiar with imperial bolt sizes, making communication and collaboration easier;

- Availability: In areas where the imperial system is the standard, hardware stores and suppliers stock a wide variety of imperial bolt sizes;

- Tradition: There may be a preference for continuity of practice in certain fields, such as those that have traditionally used imperial units.

Conclusion

Knowing what size bolts to use is critical in many fields. Whether you’re working on a building, a factory, or a do-it-yourself project, this information will help you choose the right bolt. To properly size a bolt, you need to know its diameter, thread pitch, and length. This video provides a more in-depth explanation and visual illustration of bolt sizes:

This tutorial and the accompanying bolt size charts are intended to help you navigate the sometimes-confusing world of bolt sizes.

FAQ

The three dimensions of a bolt’s dimensions are its shank diameter, thread pitch, and shank length. Millimetres in the metric system, inches in the imperial system, and threads per inch in both systems.

A bolt with a diameter of 6 millimetres (M6) in the metric system. A bolt with a 1/4-inch diameter and 20 threads per inch is known as a 1/4-20.

Check the chart for the correct bolt size. The diameter, thread pitch, and bolt length can all be determined from the respective data.

Yes, but it’s complicated because the systems employ several measurement systems. You may find tools like conversion charts and calculators on the internet to help with this.