The use of Computer Numerical Control (CNC) technology has revolutionized the manufacturing industry, with CNC milling machines becoming a staple in workshops and factories across the globe. They are automated machining tools controlled by a programmable computer and are used to perform a variety of complex cutting operations to produce precision parts from a wide array of materials.

CNC mills come in many types, each serving a different purpose:

- Vertical Mill: The spindle, which holds the cutting tool, is oriented vertically. This type of mill is ideal for plunge cuts and drilling, making it suitable for light-duty work;

- Horizontal Mill: Unlike vertical mills, horizontal mills have a horizontally oriented spindle. These mills are often used for heavy-duty operations as the cutters remove chips more easily, preventing tool breakage;

- Turret Mill: This type of mill has a stationary spindle while the table, which holds the workpiece, moves both perpendicular and parallel to the spindle axis to cut the material;

- Bed Mill: In contrast to the turret mill, the table of a bed mill moves only perpendicular to the spindle’s axis, while the spindle itself moves parallel to its own axis. This gives them more rigidity, resulting in more precise machining.

Delving into the World of Used CNC Mills

A used CNC mill is a pre-owned machine that has been used to perform milling operations. The appeal of such machines lies in their cost-effectiveness, ready availability, and depreciation value.

Cost-Effectiveness

One of the most compelling reasons to consider purchasing a used CNC mill is its cost-effectiveness. Unlike brand new machines, used CNC mills come at a fraction of the price, making them an attractive option for businesses operating on tight budgets or startups looking to minimize their initial expenditure.

Cost Savings Comparison:

| Aspect | New CNC Mill | Used CNC Mill |

| Initial Investment | High | Lower |

| Depreciation | High in early years | Stable |

| Maintenance | Similar | Similar |

| Performance | High | Dependent on quality |

Depreciation Value

A new CNC mill experiences the highest depreciation during its initial years of usage. The moment a new machine is put into operation, its value starts to decrease significantly. By opting for a used CNC mill, businesses can avoid this initial depreciation and protect their investment. Since the machine’s value has already depreciated under the previous owner, its resale value remains more stable.

Furthermore, if the used CNC mill was well-maintained and serviced regularly, its performance might be on par with a new machine. This way, companies can acquire a reliable CNC mill without the premium price tag.

Availability and Quick Setup

When it comes to new CNC mills, manufacturers often have lead times due to the manufacturing process or shipping. This waiting period can hinder businesses that require immediate access to milling capabilities. On the other hand, used CNC mills are readily available on the market and can be quickly purchased and put to use.

For manufacturers aiming to scale their production swiftly or meet urgent orders, the quick availability of used CNC mills can be a critical advantage. The faster setup time allows businesses to streamline their operations and respond to market demands promptly.

Factors to Consider When Buying Used CNC Mills

While the benefits of purchasing a used CNC mill are clear, there are certain factors that buyers should carefully consider before making a decision:

| Aspect | Details |

|---|---|

| Machine Condition | Thoroughly inspect the used CNC mill’s condition for signs of wear and tear. Request a demonstration of the machine in action if possible. Engage a professional technician for a comprehensive assessment. |

| Brand and Model | Research the reputation and reliability of the specific brand and model of CNC mill intended for purchase. Consider brands known for durability and performance over time. |

| Service History | Obtain information about the machine’s service history, including regular maintenance and past repairs. A well-maintained CNC mill is likely to offer better performance and longevity. |

| Seller Reputation | Check the reputation of the reseller or dealership if buying from one. Look for customer reviews and feedback to ensure a reliable and trustworthy purchase. |

| Compatibility with Existing Systems | Ensure that the used CNC mill is compatible with your existing manufacturing systems and software to avoid integration issues, which can lead to delays and additional costs. |

| Warranty and Support | Inquire about the availability of warranties or support packages for the used CNC mill. Having a safety net in case of unexpected issues can provide peace of mind. |

Common Misconceptions about Used CNC Mills

Lower Quality

The prevailing belief that used CNC mills inherently produce lower quality output stems from the fear of wear and tear over time. While it is true that continuous use may lead to some level of degradation, the reality is that these machines are built to withstand the test of time.

To better understand the potential of used CNC mills, let’s explore their key attributes:

- Robust Engineering: CNC mills are constructed with high-quality materials, ensuring durability and longevity. The rigidity of their structure and precision components contribute to consistent and accurate performance;

- Advanced Technology: Many used CNC mills have cutting-edge technology that remains relevant even after years of use. Their underlying control systems can often be upgraded to keep up with modern manufacturing demands;

- Well-Maintained Machines: A critical factor in determining the output quality of a used CNC mill is the level of maintenance it has received throughout its lifetime. Regular servicing, timely replacements, and proper calibration can keep the machine in excellent working condition.

It is important to understand that the perceived lower quality output from used CNC mills is not an inherent flaw but rather a consequence of neglect or inadequate upkeep. To illustrate this point, consider the following:

| Misconception | Reality |

|---|---|

| Used CNC mills deliver lower quality output. | Well-maintained used CNC mills can produce comparable output to new machines. |

| Older machines are less accurate. | Properly calibrated, older CNC mills can achieve high precision results. |

| Pre-owned mills are more prone to breakdowns. | Regular maintenance mitigates the risk of unexpected breakdowns. |

The key to unlocking the full potential of a used CNC mill lies in diligent maintenance practices. Manufacturers and buyers alike must prioritize the upkeep of these machines to maximize their performance. To ensure top-notch output quality, the following maintenance steps should be observed:

- Regular Lubrication: Adequate lubrication reduces friction, minimizing wear and tear on moving parts;

- Component Inspection: Routinely check and replace worn-out components to maintain precision and accuracy;

- Calibration: Calibrate the CNC mill regularly to fine-tune its performance and achieve precise results;

- Software Upgrades: Stay up-to-date with the latest software enhancements to optimize machine capabilities.

Limited Lifespan

The misconception surrounding the limited lifespan of used CNC mills is a common deterrent for those considering purchasing pre-owned machines. However, this notion fails to acknowledge the significant impact of proper maintenance on a CNC mill’s longevity.

The idea that used CNC mills inherently have a short remaining lifespan is flawed. Instead, a combination of factors determines the machine’s longevity, and these can be effectively managed to prolong its service life:

- Previous Usage: The history of how a CNC mill was operated and maintained in its previous life can significantly impact its current condition. Machines that received regular maintenance and were not subjected to excessive stress are more likely to have a longer lifespan;

- Material Quality: The construction of the CNC mill plays a vital role in its durability. Models built with high-quality materials are better equipped to withstand wear and tear, increasing their potential lifespan;

- Maintenance Practices: Regular servicing, lubrication, and proper routine checks are crucial to keep the CNC mill in optimal working condition. Neglecting these maintenance tasks can accelerate wear on critical components, shortening the machine’s life span.

The key to maximizing the lifespan of a used CNC mill lies in a comprehensive and proactive approach to maintenance. Manufacturers and operators can follow these guidelines to ensure the machine’s longevity:

| Maintenance Practice | Impact on Lifespan |

|---|---|

| Regular Servicing and Inspection | Identifying and addressing issues early to prevent major failures. |

| Lubrication Maintenance | Reducing friction and minimizing wear on moving parts. |

| Proper Calibration | Ensuring precision and accuracy for extended periods. |

| Temperature and Environmental Control | Preserving the machine from adverse conditions. |

| Controlled Usage within Capacity Limits | Preventing strain on the machine and its components. |

Contrary to popular belief, purchasing a well-maintained, pre-owned CNC mill can offer several advantages over buying new:

- Cost Savings: Used CNC mills typically come at a fraction of the cost of a new machine, allowing manufacturers to allocate their budget more efficiently;

- Proven Performance: With a track record of previous use, it’s easier to assess the reliability and performance of a used CNC mill before making a purchase;

- Immediate Availability: While new machines may require a waiting period, pre-owned CNC mills are readily available, expediting the setup process for production.

Obsolete Technology

The belief that used CNC mills are plagued with outdated technology is not entirely accurate. While some older models may lack the cutting-edge features of newer machines, a considerable number of pre-owned CNC mills still incorporate modern advancements. Key aspects of technology to consider include:

- Control Systems: Many used CNC mills are equipped with advanced control systems that offer high precision and efficient operation. While not always the latest models, these controls can still meet the demands of most machining tasks;

- CAD/CAM Compatibility: The capability of pre-owned CNC mills to work with current Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software is crucial for seamless integration into modern manufacturing workflows;

- Tooling and Accessories: Upgrading tooling and accessories can enhance the capabilities of used CNC mills, making them adaptable to a wide range of applications.

When considering the purchase of a used CNC mill, diligent evaluation becomes paramount. By conducting a comprehensive assessment, manufacturers can ensure that the machine aligns with their specific requirements and technology expectations. The evaluation process should encompass:

| Evaluation Aspect | Key Considerations |

|---|---|

| Technology Compatibility | Verify if the CNC mill’s technology meets your machining needs. |

| Maintenance Records | Review the machine’s maintenance history for any red flags. |

| Physical Condition and Wear | Inspect critical components for signs of wear and tear. |

| Test Runs and Performance Validation | Conduct test runs to gauge the machine’s accuracy and reliability. |

Rather than dismissing used CNC mills as outdated relics, manufacturers should recognize the value of well-maintained pre-owned machines:

- Cost-Effectiveness: Acquiring a used CNC mill can offer significant cost savings, allowing manufacturers to allocate resources strategically;

- Proven Performance: Older machines with a history of successful operation can provide reassurance of their reliability and efficiency;

- Customizability: Upgrading and retrofitting options enable manufacturers to tailor the CNC mill to suit specific production requirements.

Evaluating a Used CNC Mill

The process of assessing a used CNC mill before buying is crucial to ensure that the machine meets your needs and will offer value for money.

The Quest for Physical Perfection

Like a skilled detective, begin your investigation by carefully examining the used CNC mill for any visible signs of damage or excessive wear. To aid in your quest, let’s create a table to jot down your findings:

| Physical Damage | Observations |

|---|---|

| Chipped or broken parts | |

| Worn-out controls | |

| Damaged surfaces |

Unleashing the Power of Precision

A CNC mill’s true worth lies in its ability to produce precise parts. So, let’s put the machine’s precision to the test with a trial run. Here’s a bullet list to guide you through this endeavor:

- Load a test program and execute it on the machine;

- Observe the results and measure the dimensions of the produced parts;

- Compare the measured dimensions with the desired accuracy to assess the machine’s precision.

The Chronicles of Maintenance and Repair

A machine with a well-kept history is like a treasure chest of reliability. Delve into the maintenance and repair records to understand the CNC mill’s care and upkeep. Create another table to record the machine’s past:

| Maintenance and Repair History | Observations |

|---|---|

| Maintenance records | |

| Repair logs |

Unmasking the Seller’s Reputation

In this tale of machine hunting, choosing the right seller can be the key to a successful quest. Uncover the truth about the seller’s reputation with a blend of paragraphs and bullet points:

- Customer Reviews: Seek out online reviews or testimonials from previous buyers. Pay attention to any recurring praise or criticism about the seller’s products and services;

- Industry Certifications: Does the seller boast any industry certifications or recognitions? These accolades can signify their commitment to quality and professionalism;

- Word of Mouth: Don’t hesitate to inquire among fellow machinists or industry experts about the seller’s reputation. A positive word of mouth can serve as a golden compass to guide your decision.

Embarking on Your Decision

Now that you have diligently followed each step of the evaluation process, you possess a wealth of information about the used CNC mill and the seller. It’s time to weigh the evidence and make an informed decision. Remember, a used CNC mill with minimal physical damage, impeccable precision, well-documented maintenance, and a reputable seller is a treasure worth acquiring.

Conclusion

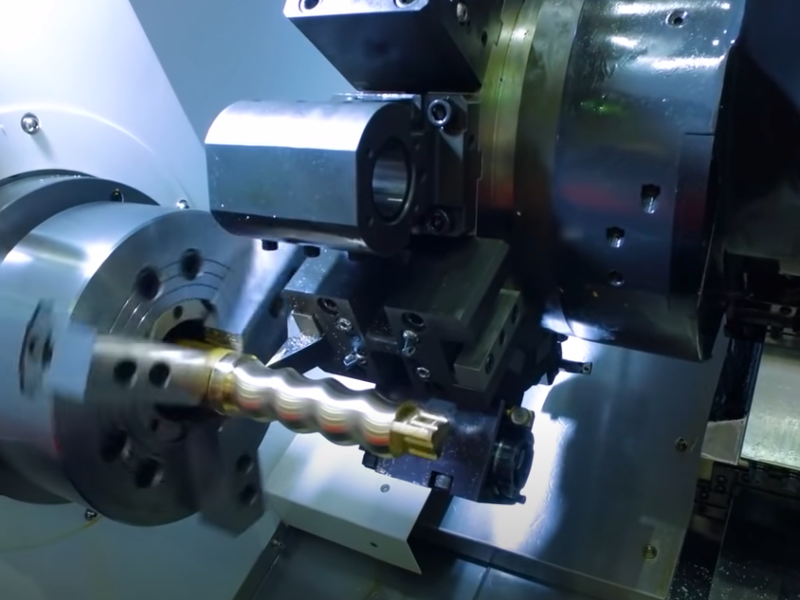

Used CNC mills are an excellent option for businesses seeking cost-effective, reliable, and versatile machining solutions. By considering the points discussed in this article and taking time for careful evaluation, you can secure a valuable asset that continues to contribute to your production line for many years. For better understanding, check this video

that provides a comprehensive demonstration and detailed discussion about used CNC mills.

FAQ

Knowing the machine’s past application gives insights into the kind of wear and tear it might have undergone. A machine used for light-duty jobs would generally be less worn than one used for heavy-duty operations.

The maintenance history provides valuable information about how well the machine has been cared for. Regular maintenance is a good indicator of a machine’s expected longevity.

Some sellers offer limited warranties for their used machines. It’s always wise to inquire about any guarantees or warranties.

The machine’s manual often holds critical information regarding its operation and maintenance. Always check if it’s available with the machine.

It’s essential to check the availability and cost of replacement parts. The lack of readily available parts can halt production if the machine breaks down, increasing downtime.