Nylon is highly esteemed in various industries for its exceptional strength, durability, and versatility. Its popularity arises from being a group of synthetic polymers with remarkable properties. However, it becomes crucial to comprehend how nylon behaves under ultraviolet (UV) radiation, especially in applications where it is exposed to outdoor conditions. This article delves into the intriguing concept of UV resistance in nylon, exploring the methods to achieve it, the advantages it brings, and the potential limitations it may encounter.

The Concept of UV Radiation

To grasp nylon’s UV resistance, it is essential to understand what UV radiation is. UV radiation is a part of the light spectrum that is invisible to the naked eye. It falls beyond the violet end of the spectrum, earning the name ‘ultraviolet.’ There are three types of UV radiation:

| UV Radiation Type | Characteristics | Impact on Living Organisms | Effect on Materials |

|---|---|---|---|

| UV-A | Longest wavelength among UV radiation types. | Least harmful to living organisms. | Causes materials to fade or discolor over prolonged exposure. |

| UV-B | Mid-range wavelength, more energetic than UV-A. | More harmful to living organisms. | Induces degradation in various materials over time. |

| UV-C | Shortest wavelength and highest energy among UV radiation types. | Highly damaging to living organisms. | Luckily, the majority of UV-C radiation is absorbed by the Earth’s protective ozone layer. |

Nylon’s Marvelous UV Resistance

Nylon, a synthetic polymer first introduced in the late 1930s, has since found a wide array of applications owing to its exceptional properties. One of its remarkable characteristics is its capability to endure the harmful effects of UV radiation, making it an excellent choice for outdoor and high-exposure applications. Let us delve into the secrets behind nylon’s radiant resilience:

- Chemical Structure: Nylon’s UV resistance can be attributed to its distinctive chemical composition. It is composed of long chains of repeating units, known as polyamides, which provide it with both strength and flexibility. These chains possess properties that allow them to absorb and disperse UV radiation without undergoing significant degradation;

- UV Absorption: When exposed to UV radiation, nylon molecules selectively absorb the incoming energy. This absorption process helps shield deeper molecular structures from potential damage by preventing the energy from reaching them. The absorbed energy is often dissipated harmlessly in the form of heat;

- Cross-Linking and Stabilization: Manufacturers frequently introduce additives or incorporate specific stabilizers into the nylon formulation. These additives enhance the material’s resistance to UV radiation by creating cross-links within the polymer matrix. These cross-links act as reinforcing bridges, fortifying the nylon against UV-induced degradation;

- Surface Treatments: In certain applications, nylon surfaces can undergo specialized treatments to further enhance their UV resistance. These treatments may involve applying UV-blocking coatings or implementing chemical modifications that create an additional protective layer.

Applications of UV-Resistant Nylon

The exceptional UV resistance of nylon paves the way for a multitude of applications, including but not limited to:

- Outdoor textiles and apparel: Nylon-based fabrics that can endure prolonged exposure to sunlight while retaining their color and structural integrity;

- Automotive components: UV-resistant nylon parts for car interiors and exteriors, guaranteeing durability and aesthetics over time;

- Outdoor equipment: Durable nylon utilized in camping gear, backpacks, and sporting equipment, capable of withstanding various outdoor elements;

- Architectural elements: UV-resistant nylon incorporated into building materials, outdoor furniture, and awnings, ensuring long-lasting performance and protection against sun exposure.

UV Resistance in Nylon

Nylon, renowned for its remarkable properties, is not immune to the mysterious impact of UV radiation. The interaction between this synthetic polymer and the invisible UV spectrum conceals secrets that can captivate and caution us. Let us embark on a journey through the effects of UV radiation on nylon, delving into the consequences of this interaction in detail:

| Effect of UV Radiation on Nylon | Description |

|---|---|

| Color Fading | One of the most apparent effects of UV radiation on nylon is the gradual fading of vibrant colors over time. When nylon products, such as textiles and outdoor gear, are consistently exposed to the sun’s UV rays, the pigments responsible for their captivating hues start to undergo photodegradation. This process leads to a reduction in color intensity, resulting in a subdued appearance. The once brilliant shades transform into muted tones, altering the aesthetic appeal of the nylon items. |

| Reduced Mechanical Strength | As the sun’s rays shower upon nylon, their invisible energy can initiate a series of molecular transformations. The polymer chains comprising the nylon material may gradually break down, leading to a reduction in its mechanical strength. Key mechanical properties like tensile strength, elongation, and impact resistance may suffer as a result. This weakening of the material compromises its capacity to withstand external forces, potentially affecting the overall performance and durability of nylon-based products. |

| Embrittlement | A particularly insidious consequence of prolonged UV exposure on nylon is its tendency to become brittle. Under the relentless assault of UV radiation, nylon molecules may undergo structural changes that make them more susceptible to cracks and breaks. This embrittlement can lead to a significant reduction in the material’s flexibility and resilience, resulting in compromised functionality and potential failure under stress. |

Understanding UV-Resistant Nylon:

As we delve into the intricacies of UV resistance in nylon, it becomes evident that not all nylon is equal in its ability to withstand the challenges posed by the sun’s rays. Manufacturers employ various strategies to enhance the UV resistance of nylon-based products, ensuring their longevity and performance. Some approaches include:

- UV Stabilizers: Integrating UV stabilizers into nylon formulations can significantly mitigate the adverse effects of UV radiation. These stabilizers act as guardians, shielding the polymer chains from the damaging energy of UV rays. By absorbing or dissipating the UV energy, they prevent it from reaching the molecular level, thus preserving the material’s mechanical properties and color vibrancy;

- Additive Blends: Combining nylon with other polymers or additives can enhance its overall UV resistance. These additive blends create a synergistic effect that fortifies nylon against the harmful impacts of UV radiation. By strategically selecting compatible materials, manufacturers can engineer nylon products that excel in challenging outdoor environments.

Improving UV Resistance

The good news is that nylon’s UV resistance can be significantly improved with certain modifications. Here are some common techniques used to increase the UV resistance of nylon:

- UV Stabilizers: These additives are mixed with the nylon during its manufacturing process. They absorb, reflect, or scatter UV radiation, reducing the amount of radiation that reaches the nylon. Additionally, they neutralize the harmful radicals formed due to UV radiation, thereby reducing the degradation of nylon;

- Carbon Black: Adding carbon black to nylon significantly improves its UV resistance. Carbon black particles can absorb almost all UV radiation and convert it into heat, which is then dissipated, preventing UV-induced degradation. This makes carbon black an effective UV stabilizer for nylon-based products exposed to outdoor conditions;

- Pigments: Certain pigments can absorb UV radiation and enhance nylon’s UV resistance. However, the type and concentration of the pigment can affect the color and other properties of the nylon. Manufacturers must carefully consider the balance between UV resistance and desired aesthetics when incorporating pigments into nylon formulations.

Benefits and Limitations

The primary benefit of UV-resistant nylon is its enhanced durability under sunlight, making it suitable for outdoor applications such as ropes, tarps, outdoor furniture, and automotive parts. Moreover, it retains its color and mechanical properties for a longer duration compared to standard nylon.

However, there are limitations to consider. Increasing nylon’s UV resistance often requires additional processing, which in turn increases the cost of the material. Additionally, certain UV stabilizers can impact other properties of nylon, such as its color or transparency. Manufacturers must strike a balance between UV resistance and preserving the desired characteristics of the nylon when incorporating UV stabilizers.

Conclusion

While nylon is susceptible to UV radiation, its resistance can be significantly enhanced through the addition of UV stabilizers, carbon black, or specific pigments. With its improved UV resistance, nylon continues to be a material of choice for many outdoor applications, offering longevity in the face of the sun’s invisible but potent rays. However, potential trade-offs regarding cost and other material properties should be carefully considered in the selection process. Manufacturers must strike a balance between achieving optimal UV resistance and maintaining the desired characteristics of the nylon-based products.

FAQ

UV radiation can degrade nylon by breaking down its polymer chains. This can cause a loss of mechanical properties, color fading, and embrittlement.

UV resistance in nylon is typically improved by adding UV stabilizers, carbon black, or certain pigments during its manufacturing process.

UV-resistant nylon retains its mechanical properties and color longer under sunlight, making it suitable for outdoor applications.

The process to increase nylon’s UV resistance can increase its cost. Some UV stabilizers can also affect other properties of nylon, like its color or transparency.

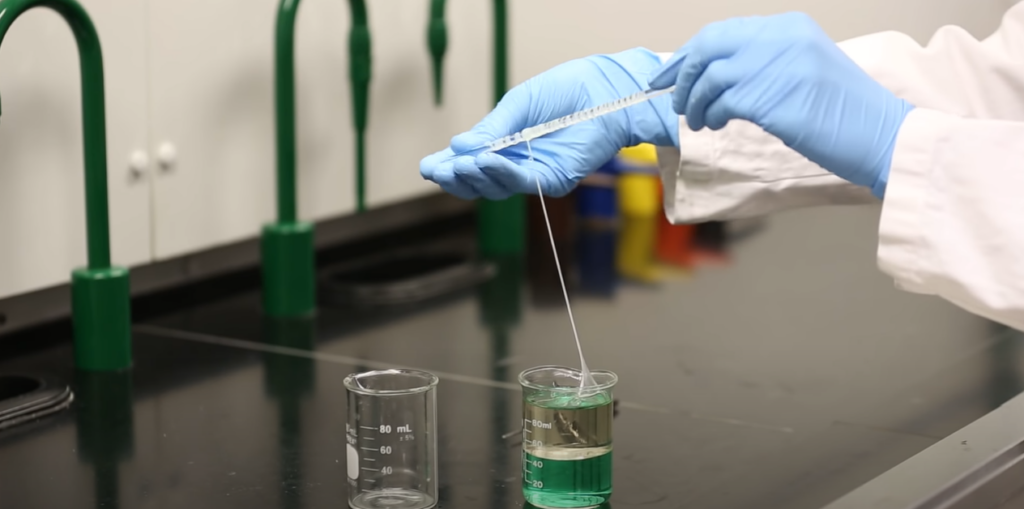

For a more vivid understanding of the interaction between nylon and UV radiation, you can refer to this insightful video [insert video link]. It visually demonstrates how UV radiation impacts nylon and how various modifications can enhance its resistance.