In the realm of lathe work, one can delve into the intricacies of this machining tool to gain a better understanding of its purpose and potential applications. If the desire to learn more about lathes arises, this is the right place to do so. Below are some fundamental aspects of lathes to shed light on what they are, how they function, and their significance in various projects.

Lathe 101: Unraveling the Essence of a Lathe

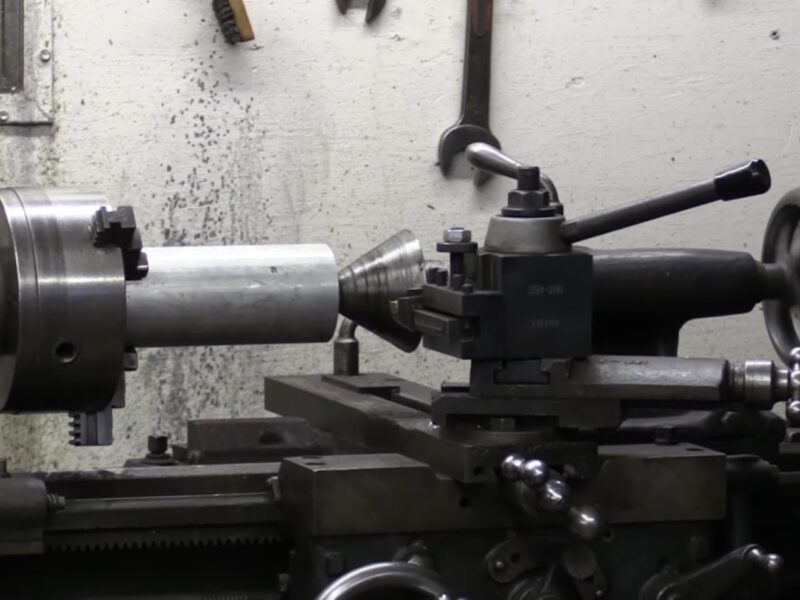

A lathe stands as a pivotal machining tool, primarily employed in shaping both metal and wood. Its operational principle involves the rotation of the workpiece around a fixed cutting tool, enabling the removal of undesired material and yielding a finely sculpted end product.

The diversity of lathes extends to specialized variants tailored to distinct materials and techniques. In the premises of All Metals Fabricating, an array of four lathes is available, including one with live tooling capabilities, allowing for multitasking jobs. Whether producing parts for machinery or crafting unique items like bowls and musical instruments, they all rely on this core principle of holding and rotating the workpiece.

Exploring the Components of a Lathe

The integral constituents of a lathe encompass the bed, headstock, tailstock, spindles, toolrest, and motor. Understanding their roles is crucial, and here’s an elucidation of their functions:

The Bed: Foundation of Stability

The bed serves as the backbone, serving as the base to which all other components are attached. It significantly influences the size capacity of the lathe, as the distance between the main spindle and the bed determines the maximum diameter possible.

Proper Orientation: A Matter of Perspective

A correct lathe setup involves the headstock positioned on the left and the tailstock on the right. One must ensure they are not standing on the wrong side to avoid any operational mishaps. The headstock, being the heart of the lathe’s action, applies the motor’s power to the workpiece, while simultaneously holding the main spindle. The motor, typically an electric variant but sometimes a hydraulic one, is found on the left, under the lathe bed, near the headstock.

Adjustments for Precision and Safety

The toolrest and tailstock are adjustable, allowing customization for specific tasks. However, it is vital to remember that these adjustments should only be made when the lathe is turned off to ensure safety. Before continuing, one should always double-check to ensure proper re-tightening after making changes.

Versatility Through Attachments and Accessories

The spindles, especially the primary rotating one that clutches the workpiece, can be equipped with various attachments and accessories. This versatility is possible due to the hollow and threaded nature of the main spindle’s exterior. Among the useful attachments are centers, chucks, and faceplates, pivotal for workpiece positioning and secure fastening.

What are the Advantages of a Lathe?

Bestowed with the title “mother of machining tools,” lathes prove indispensable for a multitude of purposes. They facilitate shaping, drilling, sanding, knurling, turning, cutting, and deformation, rendering them a versatile and prized asset for both metal and woodworking. Those seeking precision cutting and shaping capabilities will find a lathe fitting for their projects, and teams requiring a multitasking workhorse will undoubtedly benefit from its prowess, replacing the need for multiple tools.

Prioritizing Lathe Safety

While mastery over the lathe is desirable, one must not become overly complacent during its usage. Operating machinery, particularly during repetitive tasks, might inadvertently trigger an autopilot mode in the operator’s brain, leading to potential mistakes and accidents.

For a secure lathe operation, adhering to essential safety guidelines from reputable institutions such as Purdue University and West Virginia University is crucial.

The Right Equipment for Safety

Before engaging the lathe, the operator must don appropriate safety gear, such as safety glasses with side protectors or a face shield. Ensuring hair is tied up and any loose clothing, like long sleeves, is secured is essential. Wearing gloves, rings, or a watch while using the lathe is strictly forbidden, as they can pose severe hazards if entangled with the bit or spindle.

- Safeguarding with Shields and Guards. Before starting the lathe, meticulous inspection of its components and guards is imperative. If any abnormalities are observed, clear labeling indicating the issue is vital to prevent subsequent users from encountering avoidable problems;

- The Edge of Sharp Tools: A Safe Practice. Working with sharp and intact lathe tools not only enhances efficiency but also ensures safety during operation. Any dull or damaged tools should be promptly labeled and repaired before proceeding;

- The Power of Off: Adjustments Demand Caution. Making adjustments while the lathe is running is an unacceptable risk. It is imperative to wait until the lathe is completely powered off before attempting any modifications. Similarly, any maintenance tasks on the lathe should only be performed with the power source completely disconnected.

The Guidance of Expertise: Partnering with an Experienced Machine Shop

While adhering to safety protocols is crucial, experience and expertise remain unmatched in ensuring a secure lathe operation. If an individual lacks proficiency, seeking assistance from a reputable machine shop and establishing a strong partnership can guarantee satisfactory outcomes.

A lathe encompasses a multitude of roles, including that of a shaper, cutter, sander, and deformer. Its adaptability to specialized attachments makes it a crucial asset in various industries. Being an indispensable tool in the metal- and woodworking realms, its versatility sets it apart as one of the most sought-after and valued machinery pieces.

Conclusion

Exploring the world of lathe work unveils a fascinating and essential realm of machining tools. From its fundamental principles of rotating workpieces to create finely shaped results, to the diverse array of specialized lathes available for different materials and techniques, the significance of this tool cannot be understated.

- The main components of a lathe, such as the bed, headstock, tailstock, spindles, toolrest, and motor, form a cohesive system that enables precise and versatile operations. Proper orientation and adjustments ensure safe usage, while the inclusion of attachments and accessories expands the lathe’s capabilities, making it a reliable workhorse for countless tasks;

- Safety remains paramount when working with lathes, emphasizing the importance of wearing appropriate gear, checking shields and guards, and maintaining sharp tools. Following the guidelines from reputable institutions and exercising caution during adjustments further enhance the security of lathe operations;

- Ultimately, the expertise and experience of seasoned professionals in machine shops provide invaluable guidance and assurance for optimal lathe usage. With lathes serving as the “mother of machining tools,” their versatility appeals to a broad spectrum of metal- and woodworkers, empowering them to accomplish intricate tasks and produce exceptional results.

In essence, a lathe stands as a testament to human ingenuity and craftsmanship, an indispensable tool that shapes raw materials into works of art and precision components for machinery. By mastering the lathe and harnessing its capabilities, artisans and engineers alike can continue to push the boundaries of creativity and innovation in the world of manufacturing.